SAE AS 22759-12:2000 pdf download WIRE, ELECTRICAL, FLUOROPOLYMER-INSULATED, EXTRUDED TFE, NICKEL-COATED COPPER CONDUCTOR, 600 VOLT

TEMPERATURE RATING: 260°C (500°F) max conductor temperature

VOLTAGE RATING: 600 volts (rms) at sea level

SPARK TEST OF PRIMARY INSULATION: Not required

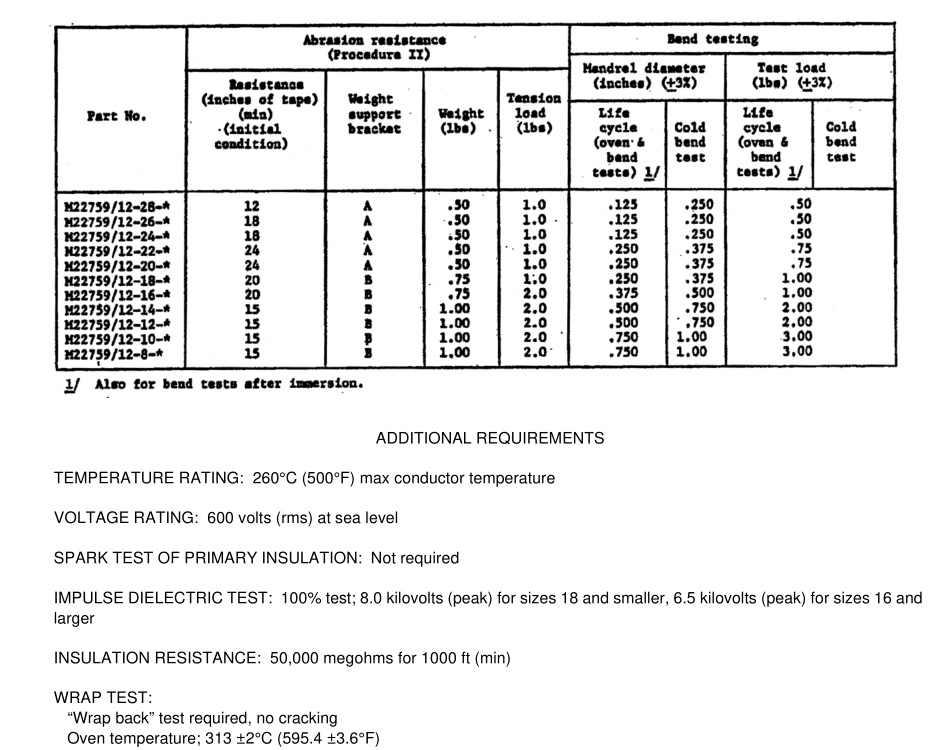

IMPULSE DIELECTRIC TEST: 1 00% test; 8.0 kilovolts (peak) for sizes 1 8 and smaller, 6.5 kilovolts (peak) for sizes 1 6 and

larger

INSULATION RESISTANCE: 50,000 megohms for 1 000 ft (min)

WRAP TEST:

“Wrap back” test required, no cracking

Oven temperature; 31 3 ±2°C (595.4 ±3.6°F)

BLOCKING: 260 ±2°C (500 ±3.6°F)

SHRINKAGE: 0.03 inch max at 290 ±2°C (554 ±3,6°F)

WICKING: No requirement

LOW TEMPERATURE (COLD BEND):

Bend temperature: -65 ±2°C (-85 ±3.6°F)

Dielectric test, 3000 volts (rms), 60 Hz

THERMAL SHOCK:

Oven temperature, 260 ±2°C (500 ±3.6°F)

Max change in measurement, 0.06 inch

FLAMMABILITY: Post-flame dielectric test not required

LIFE CYCLE:

Oven temperature 275 ±2°C (527 ±3.6°F)

Dielectric test, 3000 volts (rms), 60 Hz

DIELECTRIC TEST AFTER IMMERSION: 3000 volts (rms), 60 Hz

ACID RESISTANCE: Dielectric test, 3000 volts (rms), 60 Hz

CONDUCTOR STRAND ADHESION: Not applicable

ABRASION RESISTANCE AFTER IMMERSION: No requirement

HUMIDITY RESISTANCE: No requirement

SURFACE RESISTANCE: 500 megohm-inches (min), initial and final readings.

SMOKE: 290°C (554°F)

COLOR: In accordance with MIL-STD-1 04, Class 1 ; white preferred

COLOR STRIPING OR BANDING DURABILITY: 250 cycles (500 strokes) (min), 500 grams weight

IDENTIFICATION DURABILITY: 1 25 cycles (250 strokes) (min), 500 grams weight

WIRE LENGTH REQUIREMENTS: Schedule A

SUPERSESSION DATA: The wire of this specification sheet, by part number, replaces and supersedes the wire of MS21 986(AS) (canceled) in accordance with Table III. MS21 986(AS) included wire sizes 28 through 1 6 only.

SAE AS 22759-12:2000 pdf download