SAE AS 85075-1:2002 pdf download TIE DOWN ASSEMBLY, HELICOPTER BLADE CH-46 HELICOPTER

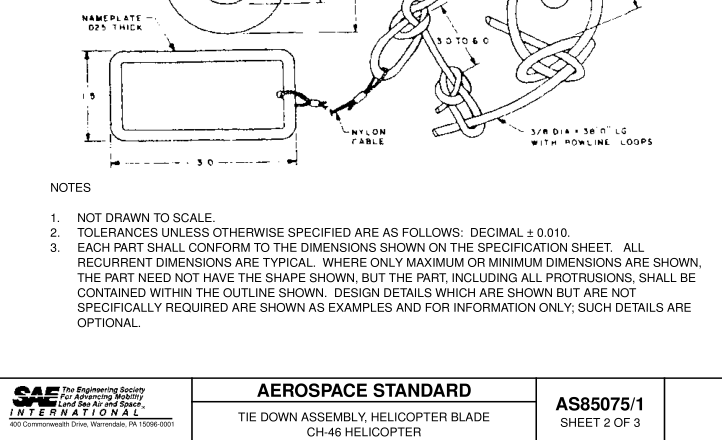

1 . NOT DRAWN TO SCALE.

2. TOLERANCES UNLESS OTHERWISE SPECIFIED ARE AS FOLLOWS: DECIMAL ± 0.01 0.

3. EACH PART SHALL CONFORM TO THE DIMENSIONS SHOWN ON THE SPECIFICATION SHEET. ALL RECURRENT DIMENSIONS ARE TYPICAL. WHERE ONLY MAXIMUM OR MINIMUM DIMENSIONS ARE SHOWN, THE PART NEED NOT HAVE THE SHAPE SHOWN, BUT THE PART, INCLUDING ALL PROTRUSIONS, SHALL BE CONTAINED WITHIN THE OUTLINE SHOWN. DESIGN DETAILS WHICH ARE SHOWN BUT ARE NOT SPECIFICALLY REQUIRED ARE SHOWN AS EXAMPLES AND FOR INFORMATION ONLY; SUCH DETAILS ARE OPTIONAL.

4. TIE DOWN ASSEMBLY SHALL MATE WITH TEST FIXTURE SHOWN TO MEET ALL REQUIREMENTS OF THIS SPECIFICATION SHEET AND MIL-T-85075 (AS). THE MATING PART IN THE ROTOR BLADE IS A RECEIVER (RI- 1 529-8) SUPPLIED TO THE HELICOPTER MANUFACTURER BY NORCO INC. OF GEORGETOWN, CONN. IT SHALL BE PREFERRED THAT THIS MATING PART (RECEIVER) BE USED FOR ALL TESTS.

5. SHACKLE SHALL PIVOT 1 80° MINIMUM ABOUT THE PIVOTING AXIS WHEN INSTALLED IN TEST FIXTURE.

6. TOTAL WEIGHT OF TIE DOWN ASSEMBLY NOT INCLUDING ROPE SHALL BE NO GREATER THAN 0.80 POUNDS.

7. TEST FIXTURE SHALL BE 1 7-4 PH STEEL, IN ACCORDANCE WITH AMS 5643, CONDITION H 1 025, AND SHALL MEET THE DIMENSIONS OF THIS SPECIFICATION.

8. THE 3/1 6 AND THE 3/8 DIAMETER NYLON ROPE SHALL BE SECURED TO THE TIE DOWN ASSEMBLY BY MEANS OF A SPLICE OR BOWLINE KNOT. A BOWLINE KNOT MAY BE USED FOR A REPLACEMENT ROPE WHEN SPLICING FACILITIES ARE NOT AVAILABLE.

. IT SHALL BE MANDATORY THAT EACH NEW SUPPLIER QUALIFY HIS TIE DOWN ASSEMBLY IN ACCORDANCE WITH THE FIRST ARTICLE INSPECTION OF PARA 4.3 OF MIL-T-85075 (AS).

SAE AS 85075-1:2002 pdf download