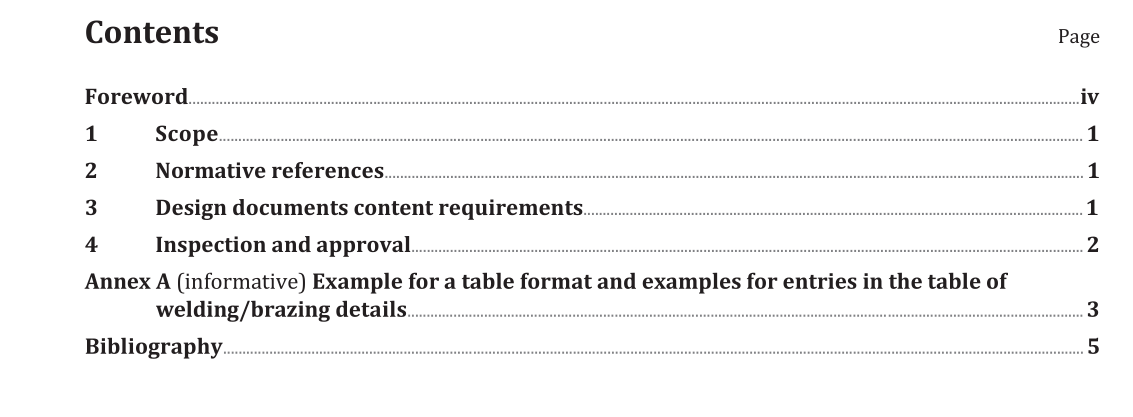

BS ISO 17533:2015 pdf download.Welding for aerospace applications — Welding information in design documents

1 Scope

This International Standard is applicable to welded and brazed metallic component parts used in aerospace construction. This International Standard specifies appropriate welding/brazing design information on drawings serving to ensure fit, form and function of welded/brazed joints.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 2553, Welding and allied processes — Symbolic representation on drawings — Welded joints

3 Design documents content requirements

Intended materials shall be clearly defined in the design documents. Additional requirements (e.g.microstructural composition, grain direction) shall be described.

On drawings, welded/brazed joints shall be depicted and indicated with a symbol according to ISO 2553. If weld/braze joint details (type, location and implementation of a weld/braze joint) cannot be identified unambiguously by means of a weld symbol, then detail shall be represented separately (e.g. sectional view of the shape of the joint with dimensions).

Information relevant to manufacturing shall be specified in a design definition and be confirmed by the cognizant welding authority.

It is recommended that information relevant to manufacturing is specified in cooperation with the design/engineering authority, manufacturing and the cognizant welding authority.

The design definition for welding/brazing details shall contain, as a minimum, the following information:

a) welding/brazing process (see ISO 4063);

b) welding/brazing specification;

c) parent material condition (for aluminium see for example EN 4632-002);

d) requirements for the welded/brazed joint, e.g. safety class, acceptance level according to

ISO/PWI 17927, ISO 16338, etc.;

e) filler material (if necessary);

f) pre-heat temperature;

g) post-weld/brazing heat treatment;

h) non-destructive testing;

i) cognizant welding authority.

If required, more details can be provided, e.g.:

— dimensional tolerances;

— accompanying samples;

— destructive testing;

— specific cleaning requirements;

— flux type.

Requirements derived from special instructions for use (e.g. class of manufacturer qualification, class of component part) shall be added.

Examples of this information in tabular form are contained in Annex A.

4 Inspection and approval

Prior to production, the cognizant welding authority shall review and approve all welding/brazing information.

BS ISO 17533:2015 pdf download