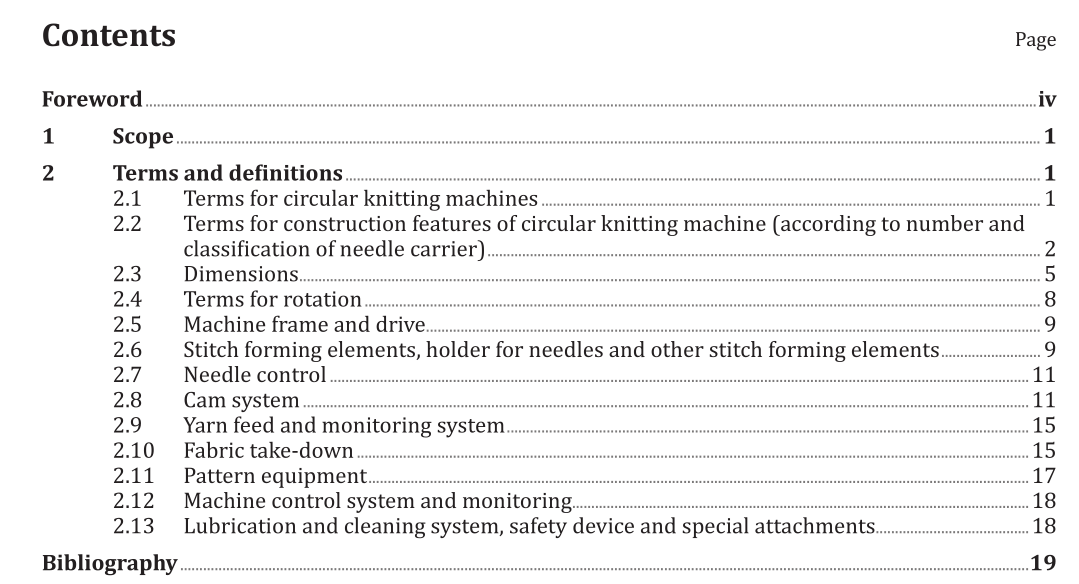

ISO 12912:2014 pdf download.Circular knitting machines — Vocabulary

1 Scope

This International Standard establishes a vocabulary of terms and a system of classification for circular knitting machines used in the textile industry for the production of weft-knitted fabrics.

NOTE See also the ISO online browsing platform (OBP): https://www.iso.org/obp/ui/

2 Terms and definitions

2.1 Terms for circular knitting machines

2.1.1 circular knitting machine

machine for the production of knitted fabrics with independent needles, longitudinally movable, in circular arrangement, with stitches formed one after the other within every course from yarn fed crosswise to the length of the fabric

[SOURCE: ISO 7839:2005, 2.1.2]

Note 1 to entry: The circular knitting machine can be specified more precisely with the following details:

— model (e.g. small, large);

— construction features (e.g. single jersey, double jersey, plain interlock, purl);

— needle type (e.g. latch or slide needle);

— number of feeders (e.g. 48 stitch feeders);

— patterning mechanism (e.g. jacquard unit).

2.1.2 small-diameter circular knitting machine

circular knitting machine with nominal diameter up to 165 mm

2.1.3 large-diameter circular knitting machine

circular knitting machine with nominal diameter of over 165 mm

2.2 Terms for construction features of circular knitting machine (according to number and classification of needle carrier)

2.2.1 RL circular knitting machine

circular knitting machine for the production of single-face fabrics (RL) by means of needles arranged in grooves of one carrier

[SOURCE: ISO 7839:2005, 2.1.2.1]

Note 1 to entry: See Figure 1.

2.8.7 knitting feeder

cam configuration with yarn guiding for producing a course or a sectional course

2.8.8 knitting clearance cam

cam for moving the needles, needle slides and other auxiliary parts into the knitting position

2.8.9 tuck clearance cam

cam for moving the needles, needle slides and other auxiliary parts into the tuck position

2.8.10 clearance cam

cam for guiding back the needles, needle slides and other auxiliary parts

2.8.11 transfer system

cam configuration without yarn guiding for transferring stitches within a stitch row

2.8.12 receiving clearance cam

cam for moving the needles, needle slides and other auxiliary parts into the receiving position when transferring stitches and loops

2.8.13 forwarding clearance cam

cam for moving the needles, needle slides and other auxiliary parts into the forwarding position when transferring stitches and loops

2.8.14 clearance cam for needle change

cam for moving needles from one needle cylinder to the other for purl fabrics

2.8.15 limiting cam

cam for limiting needle movement

2.8.16 single-part cam

cam with integrated needle butt for miss-knit, support, tuck or clearance, including guiding back of needles, needle slides or other auxiliary parts

Note 1 to entry: See Figure 13.

ISO 12912:2014 pdf download