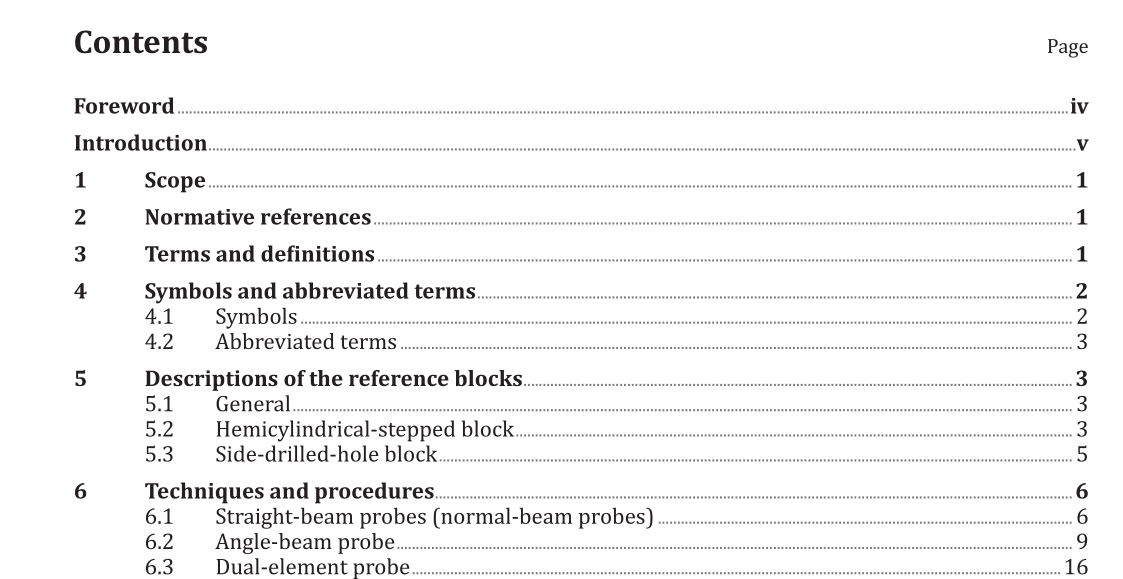

ISO 12715:2014 pdf download.Non-destructive testing — Ultrasonic testing — Reference blocks and test procedures for the characterization of contact probe sound beams

1 Scope

This International Standard introduces two metal reference blocks, the hemicylindrical-stepped (HS) block and the side-drilled-hole (SDH) block. This International Standard establishes procedures for measuring the sound beam profiles generated by probes in contact with the test object. The probes include straight-beam, angle-beam (refracted compressional and refracted shear wave), focused beam, and dual-element probes. The side dimension of the probe has to be no greater than 25 mm. The methodology of this International Standard provides guidelines for probes to be used for different metals including forged or rolled steel, aluminium, or titanium alloy products. The frequency range of the probes used in this International Standard extends from 1 MHz to 15 MHz, where 1 MHz to 5 MHz is best suited for steels and 5 MHz to 15 MHz is best for fine grain structured alloys such as aluminium products. If this International Standard is to be used for materials other than steels, users should be aware of the fact that the wave velocities in these materials can be different from that of steels and the angle-beam probes are normally designed based on the steel applications. Snell’s law of refraction is described in this International Standard so that correct angles of refraction in other homogeneous and fine-grained materials can be calculated. This International Standard applies to angle-beam probes of all practical angles (0° to 70°) and to focused and dual-element probes. This International Standard does not address the use of surface (Rayleigh) wave probes. This International Standard does not address the estimation of equivalent defect sizes which requires reference blocks with flat-bottomed holes. This International Standard establishes no acceptance criteria, but does establish the technical basis for criteria that can be defined by users.

5 Descriptions of the reference blocks

5.1 General

The two reference blocks in this International Standard are made of metal. The reference blocks shall be fabricated using a material with acoustical properties similar or equivalent to that of the test object. The general requirements for the mechanical tolerances of the blocks, surface roughness, and engraved scale should be the same as stated in ISO 7963. The geometry and dimensions of the two blocks are specified in 5.2 and 5.3.

5.2 Hemicylindrical-stepped block

Figure 1 shows the dimensions of the HS block. It shall be machined from a solid cylinder. After it is machined into cylindrical step shape, it is cut along the longitudinal axis and machined to the required surface finish. The radii of the hemicylindrical steps are 20 mm, 40 mm, 50 mm, 80 mm, 100 mm, and a slot of 85 mm and 91 mm. The width of the 20 mm to 80 mm radial steps is 25 mm; the width of the 100 mm step is 30 mm; the width of the 85 mm slot is 2 mm and the width of the 91 mm radius step is 28 mm. A line along the centre section of the slot (the x-axis), a centre line dividing the HS block in symmetry (the y-axis), and boundary lines between adjacent steps, on the flat surface, shall be engraved. When in use, the block should rest on an appropriate support. The support frame shall cause neither mechanical damage to the block nor any acoustical damping effect due to the support.

ISO 12715:2014 pdf download