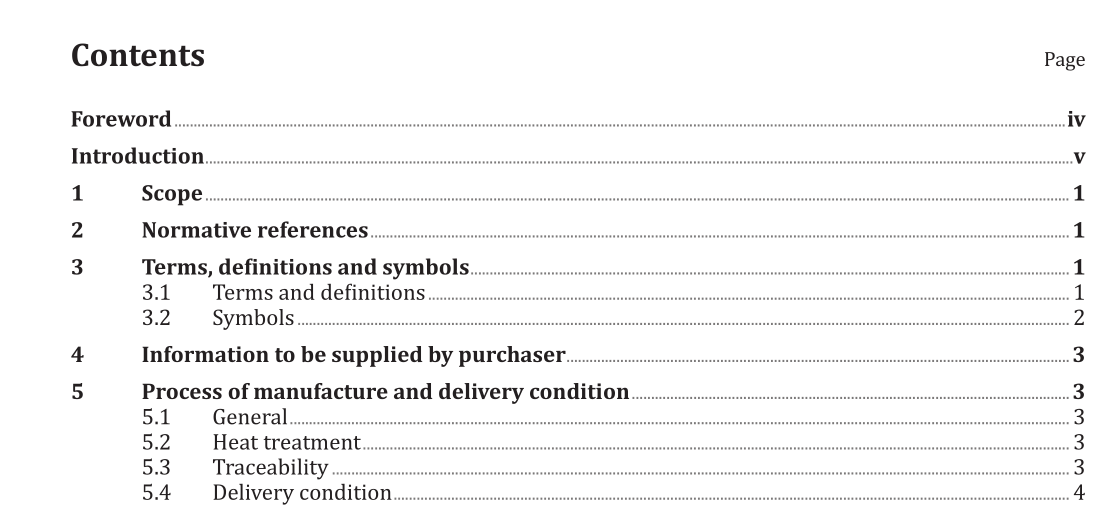

ISO 13085:2014 pdf download.Petroleum and natural gas industries — Aluminium alloy pipe for use as tubing for wells

1 Scope

This International Standard specifies the technical delivery condition, manufacturing process, material requirements, configuration and dimensions, and verification and inspection procedures for aluminium alloy pipes for use as tubing for wells in petroleum and natural gas industries.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 6892 (all parts), Metallic materials — Tensile testing

ISO 11961, Petroleum and natural gas industries — Steel drill pipe

ASTM G1, Standard practice for preparing, cleaning, and evaluating corrosion test specimens

ASTM G44, Standard practice for exposure of metals and alloys by alternate immersion in neutral 3.5% sodium chloride solution

NACE/TM 0177, Laboratory testing of metals for resistance to sulfide stress cracking and stress corrosion cracking in hydrogen sulfide (H2S) environments

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1 defect

imperfection of a size and/or population density greater than the acceptance criteria specified in this International Standard

3.1.2 heat

metal produced by a single cycle of a batch melting process

3.1.3 imperfection

discontinuity or irregularity in the product wall or on the product surface that is detectable by inspection methods outlined in this International Standard

Note 1 to entry: Imperfections are detected by methods outlined in this International Standard.

8.2 A minimum of 5 % of pipes from each lot shall be subjected to mechanical tests (but not less than two pipes). The types of tests shall be established in accordance with Table 1. If any of the test specimens representing a lot of pipes fail to conform to the requirements specified in Table 1, the manufacturer may retest double the number of specimens from this lot. If any of the specimens retested fails to conform to the specified requirements, the entire lot shall be rejected. Evaluation of the tubing mechanical properties shall be carried out on specimens taken from the upset part of the pipe. The macrostructure check shall be made on macro sections representing 2 pipes from each lot. NOTE The mechanical properties are invariably lower for the upset areas than for the pipe body.

ISO 13085:2014 pdf download