ISO 18851:2015 pdf download.Plastics piping systems — Glass-reinforced thermosetting plastics (GRP) pipes and fittings — Test method to prove the structural design of fittings

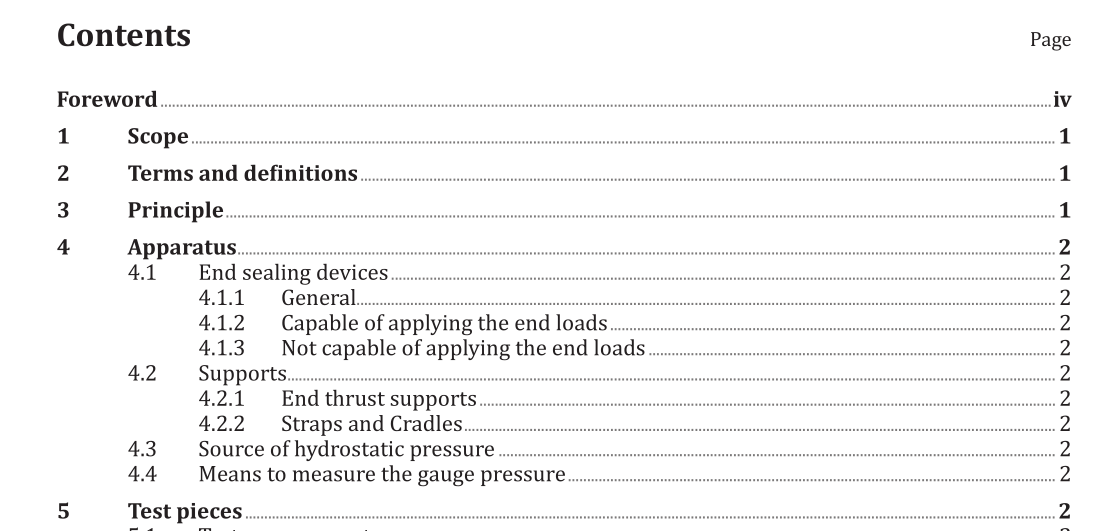

1 Scope

This International Standard specifies methods of test for fittings of any form, i.e. bends, branches, tapers, intended to be used in plastics piping systems for pressure and non-pressure drainage and sewerage or water supply made of glass-reinforced thermosetting plastics (GRP). This International Standard is applicable to fittings, in order to test their structural design, but is not applicable to connecting joint systems. It assumes that the fitting either is or is not intended to be subject to the effects of hydrostatic end thrust. The tests detailed in 8.1 to 8.4 are applicable to fittings intended to be used in buried or non-buried applications. These test procedures are applicable to fittings of all nominal sizes specified in the referring standard. The tests are for evaluating fittings intended for use in applications conveying liquids at temperatures specified in the referring standards. The test procedures in this International Standard are damaging to the test piece which will not be suitable for reuse after these tests. The test procedure is applicable to type testing. NOTE This International Standard is not intended to be used for the assessment of the performance of non- integrated joints as there are already international test methods for this purpose. See Bibliography.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1 pressure

hydrostatic gauge pressure

3 Principle

A fitting is subjected to a specified internal pressure with or without end thrust. The procedure includes prolonged static tests at elevated pressures.

At the end of each of the tests, the test piece is inspected for signs of failure as defined in 8.2.

It is assumed that the following test parameters are set by the standard making reference to this International Standard:

a) number of test pieces to be used (see 5.2);

b) if applicable, conditioning other than given in Clause 6;

c) test temperature and its permissible deviations (see Clause 7);

d) nominal pressure relevant to the fitting under test (see 5.1 and Clause 8);

e) if applicable, any criteria indicative of structural damage to the fitting [see Clause 8 and Clause 9 i)];

f) whether the fitting is or is not to be tested with end loads.

4.2 Supports

4.2.1 End thrust supports If required, the end thrust supports shall comprise part of the test rig and shall be capable of supporting the end thrust induced by the internal pressure but shall not otherwise support the fitting. Non-end thrust loaded fittings can be tested using appropriately designed reinforced concrete encasements. For branches, the branch pipe shall be designed to resist end-loading due to end thrust. The header pipe can be tested either with or without the end-load thrust

ISO 18851:2015 pdf download