ISO 20714:2019 pdf download.E-liquid – Determination of nicotine, propylene glycol and glycerol in liquids used in electronic nicotine delivery devices – Gas chromatographic method

5.4 Internal standards of high purity: quinaldine [ CAS: 91-63-4 ], 1,3-butanediol (CAS: 107-88-0), n-heptadecane (CAS: 629-78-7), n-octadecane (CAS: 593-45-3). Anethol and other appropriate internal standards may be used after assessment of their purity and determination that the internal standard does not co-elute with other components in the dilution. The peak area of the internal standard on samples should be monitored for consistency. In cases where inconsistencies are found, analysis of a diluted sample without the internal standard should be performed to confirm the absence of a peak in the extract eluting at the same time as the internal standard.

5.5 Dilution solution: isopropanol containing an appropriate concentration of the internal standard 0,2 mg/ml of quinaldine, 1 mg/ml of 1,3-butanediol, 1 mg/ml of n-heptadecane or 1 mg/ml of n-octadecane

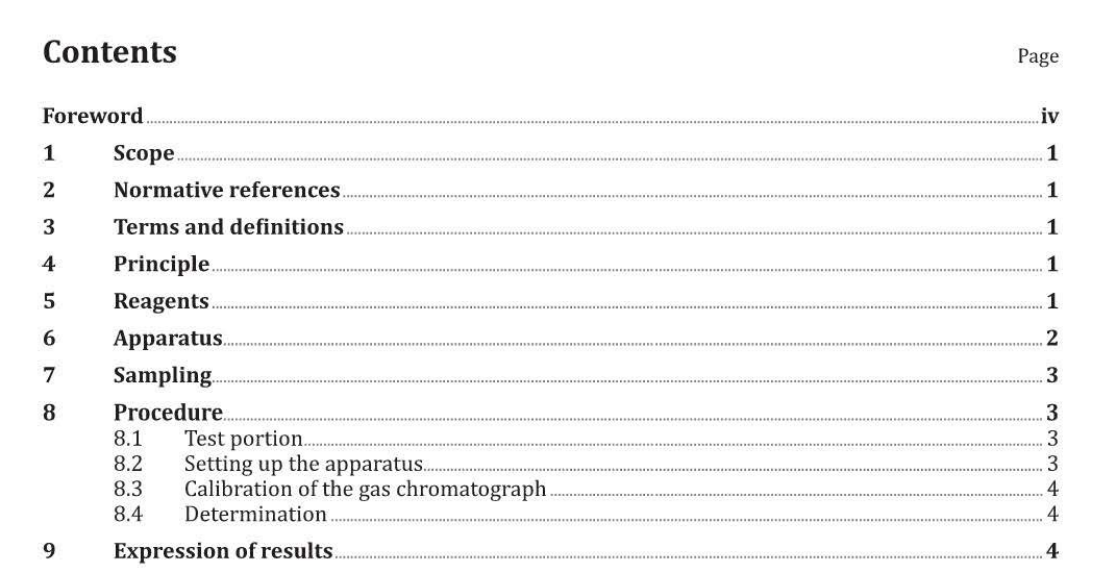

8.3 Calibration of the gas chromatograph

Inject an aliquot [ 1 µI ] ofeach of the calibration solutions ( .S.Z. ) into the gas chromatograph. Record the peak areas of nicotine, propylene glycol, glycerol, and internal Calculate the ratio of the nicotine, propylene glycol and glycerol peak areas to the appropriate internal standard peak area for each of the calibration solutions. Plot the graphs of the nicotine, propylene glycol and glycerol concentrations in accordance with the area ratios, and calculate linear regression equations (concentration of nicotine, propylene glycol and glycerol according to the area ratios) from these data . The graphs should be linear and the regression lines should not be forced through the origin. A calibration solution should be run as a quality control per iodically throughout the analysis sequence to verify that each calibration curve remains valid.

10 Repeatability and reproducibility

An interlaboratory study involving 19 laboratories was conducted. Test samples consist of seven e-liquids with varying percentages of target compounds and different flavours. The following values for the rep.eatability limits the reproducibility limits [ R ] were obtained. The difference between two single results found on matched e-liquid samples by one operator using the same apparatus within the shortest feasible time interval will exceed the repeatability limit average not more than once in 20 cases in the normal and correct operations of the method. Single resu lts on matched e -li quid samples reported by two laboratories will differ by more than the reproducibility limit (R) on average not more than one in 20 cases in the normal and correct operation of the method.

ISO 20714:2019 pdf download