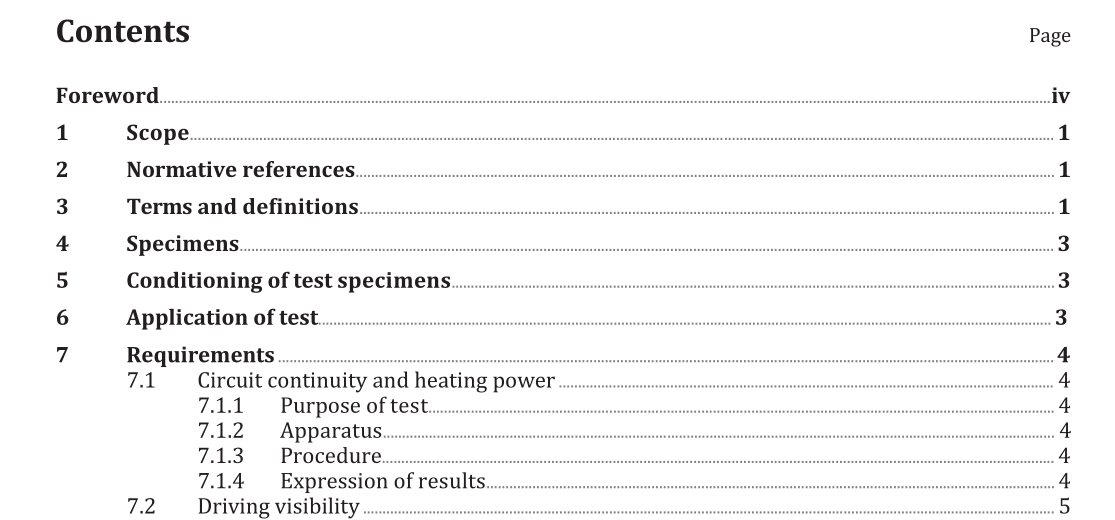

BS ISO 17449:2015 pdf download.Road vehicles — Safety glazing materials — Test methods for properties of electrically heated glazing

1 Scope

This International Standard provides the test methods and acceptance criteria for circuit continuity and heating power, driving visibility, electrical attachment bond performance, electrical attachment bending performance, hot spot identification and heating uniformity, defrosting efficiency, high voltage durability,low temperature performance and long term humidity durability, for all electrically heated safety glazing materials in a road vehicle. This International Standard provides test protocols for the static performance of an electrically heated glazing material; it is not representative of in-vehicle performance.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3538, Road vehicles — Safety glazing materials — Test methods for optical properties

IEC 60051–2, Direct acting indicating analogue electrical measuring instruments and their accessories,Part 2 — Special requirements for ammeters and voltmeters

3 Terms and definitions

For the purpose of this document, the following terms and definitions apply.

3.1 heating evaluation area

for Type 1 (3.7), represented by an area formed by outermost conductors at an extended distance of 20 mm wider than the bus bars (along the edges) and extended to 50 mm on both the top and bottom, in the absence of specific requirements and for a glazing equipped with heating circuits formed by evenly distanced conductive lines and bus bars near to the glass edges

Note 1 to entry: If the extended distance is over the edge of the glass, then take the glass edge as the border of evaluation area. The size of this generated area is calculated using CAD, see Figure 1. For other specifically designed heaters with e.g. circular shaped heater, product specification can be referenced for the heating evaluation area.

for Type 2 (3.8) and Type 3 (3.9), shall be the same as the area of the heating elements themselves, in the absence of special requirements

Note 2 to entry: No additional area shall be included.

7.1.3 Procedure

7.1.3.1 Circuit continuity

For Type 1 parts, supply the voltage defined in product specification to the electrical attachments of the part. Lay heat sensitive paper across the heating line/conductor. Optionally, use a thermal camera to check the part after power is supplied. For Type 2 parts, supply the voltage defined in product specification to the electrical attachments of the part. Set the part vertically between the projector and a display screen. Light is projected through the part to the display screen. Wires with light shadow on the screen are broken wires. For Type 3 parts, supply the voltage defined in product specification to the electrical attachments of the part, record value of ampere meter.

BS ISO 17449:2015 pdf download