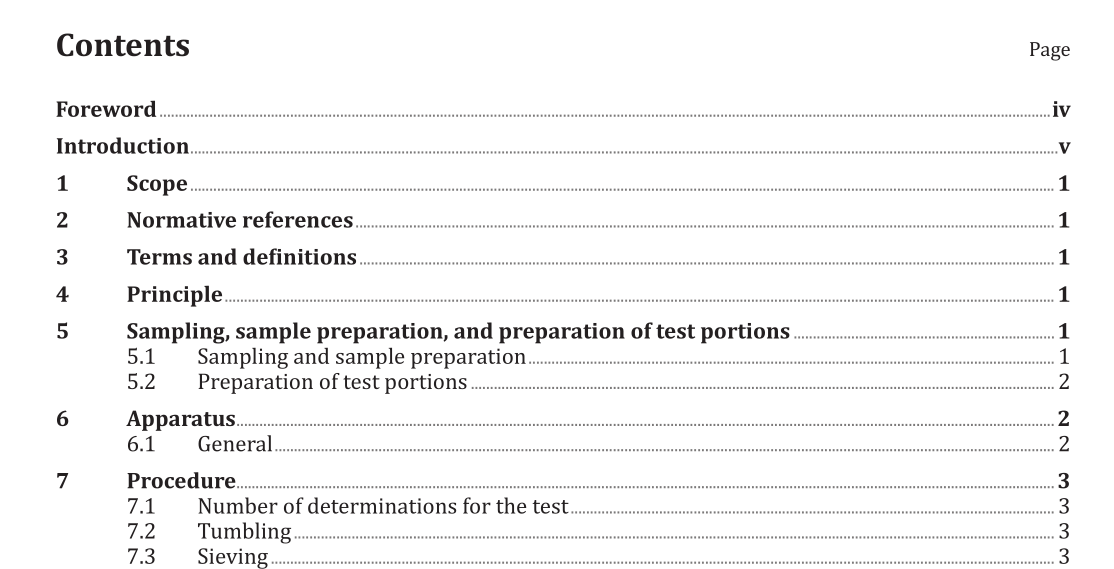

ISO 3271:2015 pdf download.Iron ores for blast furnace and direct reduction feedstocks — Determination of the tumble and abrasion indices

1 Scope

This International Standard specifies a method to provide a relative measure for evaluating the resistance of iron ores to size degradation by impact and abrasion. It covers the determination of the tumble and abrasion indices.

This International Standard is applicable to lump ores, sinters, and hot-bonded pellets.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3082, Iron ores — Sampling and sample preparation procedures

ISO 3310–1, Test sieves — Technical requirements and testing — Part 1: Test sieves of metal wire cloth

ISO 3310–2, Test sieves — Technical requirements and testing — Part 2: Test sieves of perforated metal plate

ISO 11323, Iron ore and direct reduced iron — Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 11323 apply.

4 Principle

The test portion is tumbled in a circular drum for a total of 200 revolutions, at 25 r/min. The product material is sieved with test sieves having square openings of 6,30 mm and 500 μm. The tumble index is expressed as the mass percentage of material greater than 6,30 mm and the abrasion index as the mass percentage of material less than 500 μm.

5 Sampling, sample preparation, and preparation of test portions

5.1 Sampling and sample preparation

Sampling of a lot and preparation of a test sample shall be in accordance with ISO 3082.

The size range for pellets shall be −40,0 mm + 6,30 mm.

The size range for sinters and lump ores shall be −40,0 mm + 10,0 mm.

A test sample of at least 60 kg, on a dry basis, of the sized material shall be obtained.

6.2 Tumble drum, made of steel plate at least 5 mm in thickness, having an internal diameter of 1 000 mm and an internal length of 500 mm. Two equally spaced L-shaped steel lifters 50 mm flat × 50 mm high × 5 mm thick and 500 mm long shall be solidly attached longitudinally inside the drum by welding, in such a manner as to prevent accumulation of material between the lifter and drum. Each lifter shall be fastened so that it points towards the axis of the drum, with its attached leg pointing away from the direction of rotation, thus providing a clear unobstructed shelf for lifting the sample. The door shall be so constructed as to fit into the drum to form a smooth inner surface. During the test, the door shall be rigidly fastened and sealed to prevent loss of the sample. The drum shall be rotated on stub axles attached to its ends by flanges welded so as to provide smooth inner surfaces. The drum shall be replaced, in any case, when the thickness of the plate is reduced to 3 mm in any area. The lifters shall be replaced when the height of the shelf is reduced to less than 47 mm.

ISO 3271:2015 pdf download