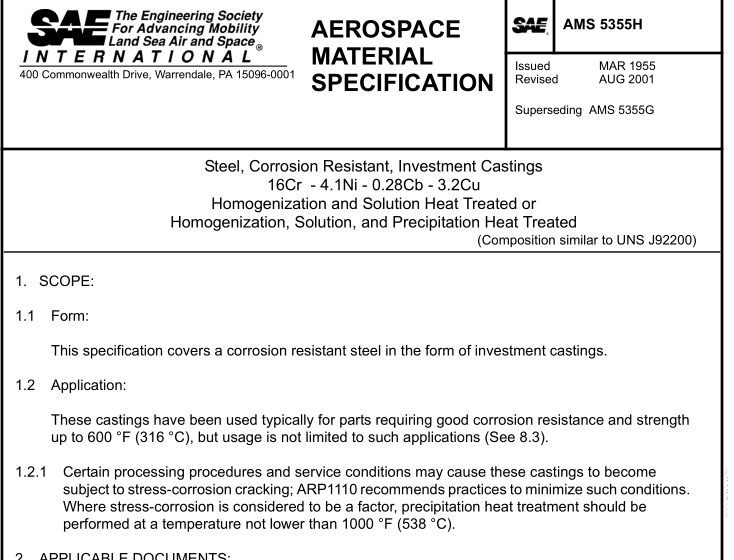

SAE AMS 5355:2001 pdf download Steel, Corrosion Resistant, Investment Castings 16Cr – 4.1Ni – 0.28Cb – 3.2Cu Homogenization and Solution Heat Treated or Homogenization, Solution, and Precipitation Heat Treated

1. SCOPE:

1.1 Form: This specification covers a corrosion resistant steel in the form of investment castings.

1.2 Application: These castings have been used typically for parts requiring good corrosion resistance and strength up to 600 °F (316 °C), but usage is not limited to such applications (See 8.3).

1.2.1 Certain processing procedures and service conditions may cause these castings to become subject to stress-corrosion cracking; ARP1110 recommends practices to minimize such conditions. Where stress-corrosion is considered to be a factor, precipitation heat treatment should be performed at a temperature not lower than 1000 °F (538 °C).

2. APPLICABLE DOCUMENTS: The issue of the following documents in effect on the date of the purchase order forms a part of this specification to the extent specified herein. The supplier may work to a subsequent revision of a document unless a specific document issue is specified. When the referenced document has been canceled and no superseding document has been specified, the last published issue of that document shall apply.

2.1 SAE Publications:

Available from SAE, 400 Commonwealth Drive, Warrendale, PA 15096-0001.

AMS 2248 Chemical Check Analysis Limits, Corrosion and Heat Resistant Steels and Alloys,Maraging and Other Highly-Alloyed Steels, and Iron Alloys

AMS 2360 Room Temperature Tensile Properties of Castings

AMS 2694 Repair Welding of Aerospace Castings

AMS 2804 Identification, Castings

ARP1110 Minimizing Stress Corrosion Cracking in Wrought Forms of Steel and Corrosion Resistant Steels and Alloys

2.2 ASTM Publications:

Available from ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959.

ASTM E 8 Tension Testing of Metallic Materials

ASTM E 8M Tension Testing of Metallic Materials (Metric)

ASTM E 18 Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials

ASTM E 353 Chemical Analysis of Stainless, Heat Resisting, Maraging, and Other Similar Chromium-Nickel-Iron Alloys

ASTM E 1417 Liquid Penetrant Examination

ASTM E 1444 Magnetic Particle Examination

ASTM E 1742 Radiographic Examination

2.3 U.S. Government Publications:

Available from DODSSP, Subscription Services Desk, Building 4D, 700 Robbins Avenue,Philadelphia, PA 19111-5094.

MIL-H-6875 Heat Treatment of Steels, Process for

MIL-STD-2175 Castings, Classification and Inspection of

QQ-P-35 Passivation Treatments for Corrosion Resistant Steel

3. TECHNICAL REQUIREMENTS:

3.1 Composition:

Castings shall conform to the percentages by weight shown in Table 1, determined by wet chemical methods in accordance with ASTM E 353, by spectrochemical methods, or by other analytical methods acceptable to purchaser (See 8.2.1 and 8.2.2).

3.1.1 Vendor may test for any element not listed in Table 1 and include this analysis in the report of 4.5.Limits of acceptability may be specified by purchaser (See 8.2.3).

3.1.2 Check Analysis: Composition variations shall meet the applicable requirements of AMS 2248.

3.2 Melting Practice:

Castings and specimens shall be poured at the casting vendor’s facility either from a melt (See 8.2.4) of a master heat or directly from a master heat (See 8.2.5).

SAE AMS 5355:2001 pdf download