SAE AMS 5549:2001 pdf download Steel, Corrosion and Heat Resistant, Plate 15.5Cr – 4.5Ni – 2.9Mo – 0.1 ON Solution Heat Treated

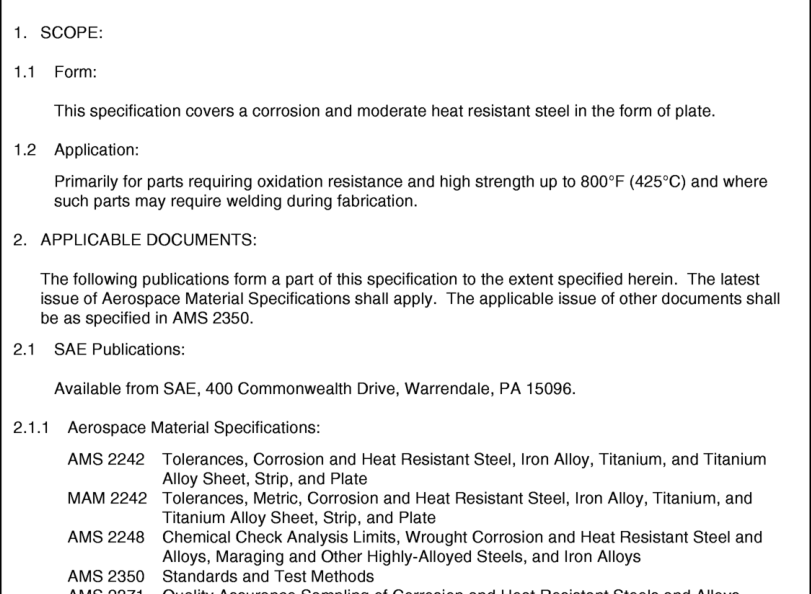

1 . SCOPE:

1 .1 Form:

This specification covers a corrosion and moderate heat resistant steel in the form of plate.

1 .2 Application:

Primarily for parts requiring oxidation resistance and high strength up to 800°F (425°C) and where such parts may require welding during fabrication.

2. APPLICABLE DOCUMENTS:

The following publications form a part of this specification to the extent specified herein. The latest issue of Aerospace Material Specifications shall apply. The applicable issue of other documents shall be as specified in AMS 2350.

2.1 SAE Publications:

Available from SAE, 400 Commonwealth Drive, Warrendale, PA 1 5096.

2.1 .1 Aerospace Material Specifications:

AMS 2242 Tolerances, Corrosion and Heat Resistant Steel, Iron Alloy, Titanium, and Titanium Alloy Sheet, Strip, and Plate

MAM 2242 Tolerances, Metric, Corrosion and Heat Resistant Steel, Iron Alloy, Titanium, and Titanium Alloy Sheet, Strip, and Plate

AMS 2248 Chemical Check Analysis Limits, Wrought Corrosion and Heat Resistant Steel and Alloys, Maraging and Other Highly-Alloyed Steels, and Iron Alloys

AMS 2350 Standards and Test Methods

AMS 2371 Quality Assurance Sampling of Corrosion and Heat Resistant Steels and Alloys, Wrought Products Except Forgings and Forging Stock

2.2 ASTM Publications:

Available from American Society for Testing and Materials, 1 91 6 Race Street, Philadelphia, PA 1 91 03.

ASTM A370 Mechanical Testing of Steel Products

ASTM E353 Chemical Analysis of Stainless, Heat-Resisting, Maraging, and Other Similar Chromium-Nickel-Iron Alloys

2.3 U.S. Government Publications:

Available from Commanding Officer, Naval Publications and Forms Center, 5801 Tabor Avenue,Philadelphia, PA 1 91 20.

2.3.1 Military Standards:

MIL-STD-1 63 Steel Mill Products, Preparation for Shipment and Storage

3. TECHNICAL REQUIREMENTS:

3.1 Composition:

Shall conform to the following percentages by weight, determined by wet chemical methods in accordance with ASTM E353 or by spectrographic or other analytical methods approved by purchaser:

Carbon

Manganese

Silicon

Phosphorus

Sulfur

Chrom i um

Nickel

Molybdenum

Nitrogen

min max

0.1 0 0.15

0.50 1 .25

— 0.50

— 0.040

— 0.030

1 5.00 1 6.00

4.00 5.00

2.50 3.25

0.07 0.1 3

3.1 .2 Check Analysis: Composition variations shall meet the applicable requirements of AMS 2248.

3.2 Condition:

Hot rolled, solution heat treated free from continuous carbide network, and descaled.

3.3 Solution Heat Treatment:

The product shall be solution heat treated by heat to 1 900°F k 25 (1 040°C k 1 5), holding at heat for 1 – 3 hr, and quenching in water or otherwise cooling as rapidly as possible to room temperature.

3.4 Properties: The product shall conform to the following requirements, tensile, bend, and hardness testing shall be performed in accordance with ASTM A370:

3.4.1 As Solution Heat Treated:

3.4.1 .1 Bending: Plate 0.750 in. (1 8.75 mm) and under in nominal thickness shall withstand, without cracking, bending at room temperature through the angle shown below around a diameter equal to three times the nominal thickness of the plate with axis of bend parallel to the direction of rol ling :

SAE AMS 5549:2001 pdf download