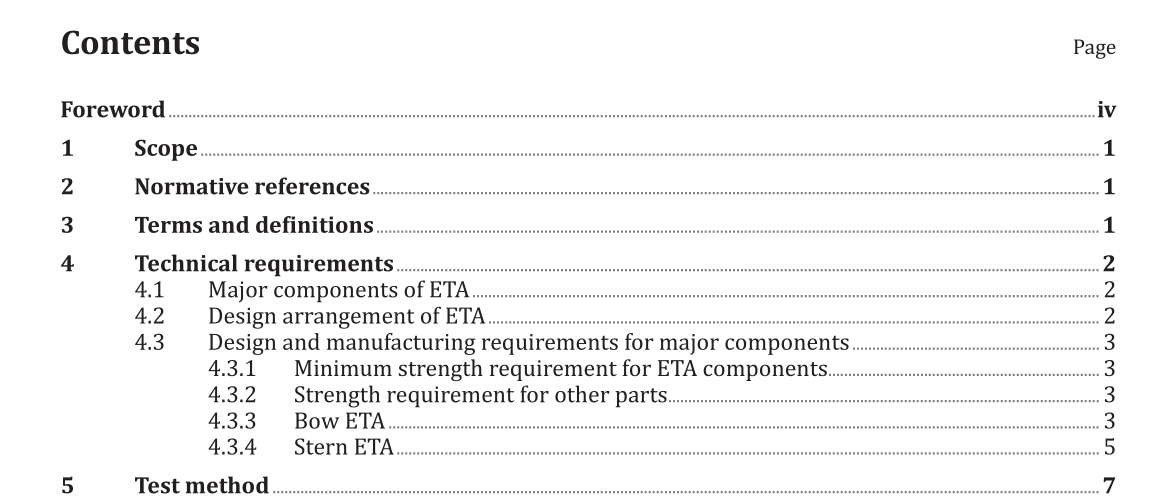

ISO 21130:2019 pdf download.Ships and marine technology — Major components of emergency towing arrangements

1 Scope

This document specifies the technical requirements, test methods, inspection rules and markings for major components of emergency towing arrangements (ETA) provided for tankers, gas carriers (LPG,LNG, etc.) and chemical vessels no less than 20 000 deadweight tonnes (DWT).

It is only applicable to emergency towing arrangements as defined in 3.1.

NOTE For any other applications, such as for mooring at a single point mooring (SPM) facility, the appropriate standards need to be referred to.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3808, Road vehicles — Unscreened high-voltage ignition cables — General specifications, test methods and requirements

ISO 4306-1, Cranes — Vocabulary — Part 1: General

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 4306-1, ISO 3808 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1 emergency towing arrangement

ETA

system equipped on tankers, gas carriers and chemical vessels, used to tow the vessel in an emergency such as mechanical failure or lack of power

Note 1 to entry: The International Maritime Organization (IMO) requires that tankers, gas carriers and chemical vessels of not less than 20 000 DWT and constructed since Jan 1, 1996, be provided with emergency towing arrangements installed on both the bow and the stern.

3.2 safe working load

SWL

maximum permissible load determined after the equipment has been tested according to the relevant regulations

5.1 Bow ETA

5.1.1 Prototype strength test for the bow ETA

a) Magnetic particle inspection shall be carried out on the fairlead, chain stopper and chafing chain prior to the test so as to ensure they are free from defects.

b) Using the SWL requirements of 4.2.1 and 4.3.1, the fairlead, chain stopper and chafing chain shall be tensioned to twice the SWL.

c) Tension force shall be gradually applied to the components and the maximum tension held for 1 min.

d) After the test, the prototype shall be examined for any failures, including unacceptable deformations.

e) The prototype of an ETA arrangement that was strength-tested shall not be installed on board.

5.1.2 Fairlead

a) A physical and chemical inspection shall be carried out for the material test rods, and the inspection results shall conform to the corresponding material standards.

b) A magnetic particle inspection shall be carried out during the manufacturing process but after surface polishing; the product shall be free from defects that affect its intended use, such as cracks,sand holes and pores.

ISO 21130:2019 pdf download