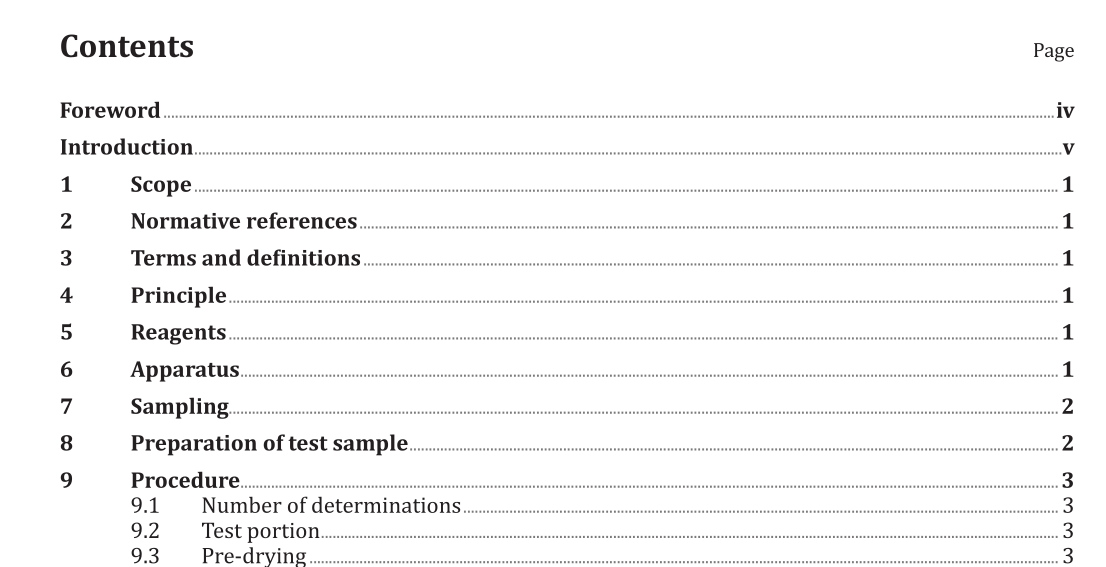

ISO 734:2015 pdf download.Oilseed meals — Determination of oil content — Extraction method with hexane (or light petroleum)

1 Scope

This International Standard specifies a method for the determination of the hexane extract (or light-petroleum extract), called “oil content”, of meals (excluding compounded products) obtained by the extraction of oil from oilseeds by pressure or solvents.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 771, Oilseed residues — Determination of moisture and volatile matter content

ISO 5502, Oilseed residues — Preparation of test samples

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 oil content

all of the substances extracted under the operating conditions specified in this International Standard,and expressed as a mass fraction, in percent, of the product as received

Note 1 to entry: The oil content may also be expressed relative to dry matter.

4 Principle

A test portion of the product is extracted in a suitable apparatus, with technical hexane or, failing this,light petroleum. The solvent is eliminated and the extract obtained is weighed.

5 Reagents

Use only reagents of recognized analytical grade, unless otherwise specified.

5.1 Technical hexane, n-hexane or light petroleum, essentially composed of hydrocarbons with six carbon atoms.

Less than 5 % shall distil below 50 °C and more than 95 % between 50 °C and 70 °C.

For any of these solvents, the residue on complete evaporation shall not exceed 2 mg per 100 ml.

6 Apparatus

Usual laboratory apparatus and, in particular, the following.

6.1 Mechanical grinder, easy to clean and allowing the meals to be ground, without heating and without appreciable change in moisture, volatile matter and oil content, to obtain particles which pass completely through a sieve of aperture size 1 mm.

6.2 Mechanical microgrinder, of the Dangoumau type 1) capable of producing a fineness of grinding of oilseed meals of less than 160 μm, with the exception of the “shell” whose particles may reach 400 μm. In laboratories where a microgrinder is not available, microgrinding of the ground sample (see 9.4.3) may be replaced by trituration with a pestle and mortar, in the presence of about 10 g of sand that has been washed with hydrochloric acid and then calcined. However, grinding in a mortar cannot be applied in the case of multiple analyses because operator fatigue prevents sufficiently efficient grinding of numerous samples, and the extraction of oil from a coarsely ground sample can never be complete.

ISO 734:2015 pdf download