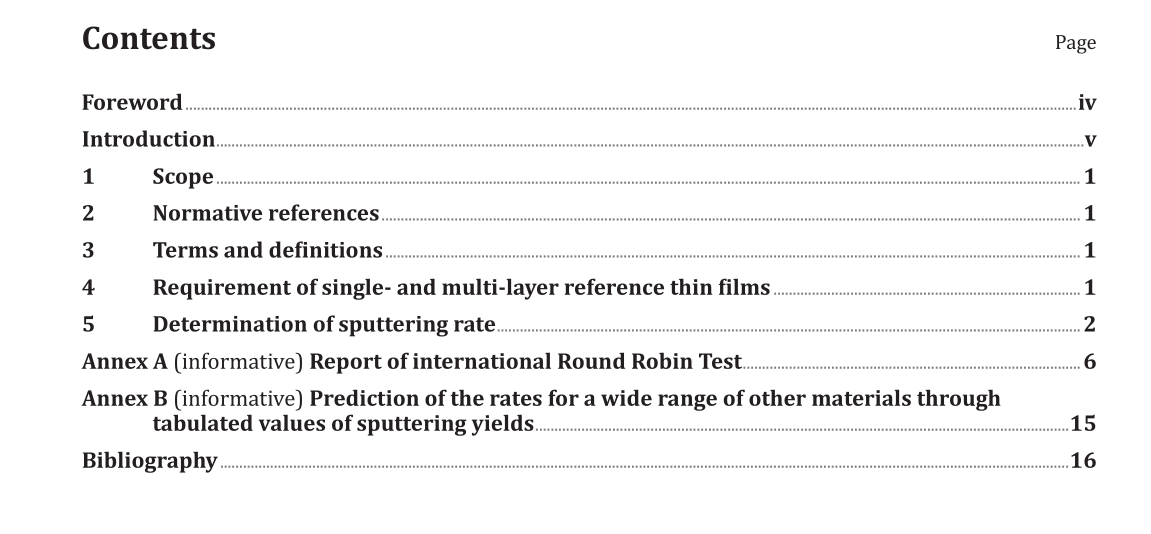

ISO 17109:2015 pdf download.Surface chemical analysis — Depth profiling — Method for sputter rate determination in X-ray photoelectron spectroscopy

1 Scope

This International Standard specifies a method for the calibration of the sputtered depth of a material from a measurement of its sputtering rate under set sputtering conditions using a single- or multi-layer reference sample with layers of the same material as that requiring depth calibration. The method has a typical accuracy in the range 5 % to 10 % for layers 20 nm to 200 nm thick when sputter depth profiled using AES, XPS, and SIMS. The sputtering rate is determined from the layer thickness and the sputtering time between relevant interfaces in the reference sample and this is used with the sputtering time to give the thickness of the sample to be measured. The determined ion sputtering rate can be used for the prediction of ion sputtering rates for a wide range of other materials so that depth scales and sputtering times in those materials can be estimated through tabulated values of sputtering yields and atomic densities.

4.2 The surface and the interfaces shall be flat and parallel to each other to avoid any distortion of sputter depth profiles. The surface roughness is often measured using atomic force microscopy and the thickness variation using transmission electron microscopy. The surface roughness of sample and the thickness variation of each layer shall be smaller than the sum of the projected range of the sputtering ions and the information depth of the analytical method.

4.3 The thickness of each layer in multi-layer thin films and the thickness of single-layer thin films shall be determined by high resolution cross-sectional transmission electron microscopy, grazing incidence X-ray reflectivity, medium energy ion scattering spectroscopy, or other appropriate methods for which an accurate uncertainty of measurement can be evaluated.

4.4 The number of A/B layer pairs in the multi-layered reference thin films shall be greater than two since profiles of the first layer A and the last layer B shall not be used due to the surface and the final interface transient effects.

4.5 For single-layer thin films, to minimize any likely contamination or surface oxidation problems, materials like gold on Si or SiO 2 on Si and Ta 2 O 5 on Ta which are stable and remain clean or can easily be cleaned are recommended.

5.3 Measure the sputter depth profile of a single- or multi-layer reference thin film and determine the interface position by the point where the signal intensity of the element reaches 50 % of its value between the lower plateau where the element is essentially absent and the upper plateau level for the layer where it is present. The determination of the interface position by this procedure is applied to this International Standard until the development of an ISO Standard for interface position. The average intensity in the upper plateau region is the plateau intensity (I upper ). This shall be calculated by summing the intensity for each measurement where the intensity is greater than 95 % of the maximum intensity and dividing by the number of measurements used in the summation.

ISO 17109:2015 pdf download