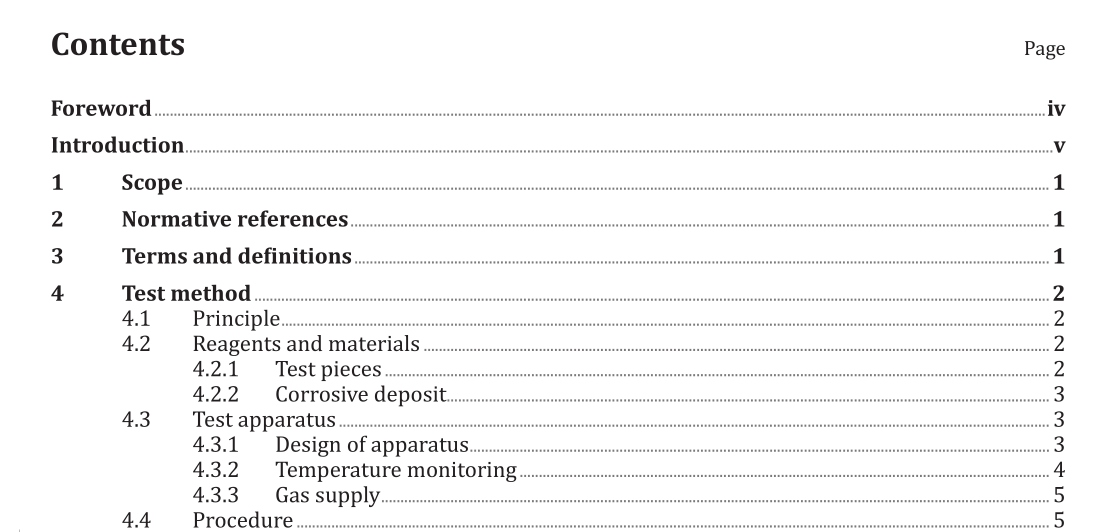

ISO 17224:2015 pdf download.Corrosion of metals and alloys — Test method for high temperature corrosion testing of metallic materials by application of a deposit of salt, ash, or other substances

1 Scope

This International Standard specifies the method for high temperature corrosion testing of metallic materials by applying a deposit of salt, ash, and/or other substances and exposing them to high temperature in a controlled gas environment to evaluate their corrosion resistance. The deposit is applied prior to high temperature exposure by spraying, dipping, or painting. This International Standard does not cover methods where test pieces are fully or partially embedded in corrosive substances or immersed in liquids. These methods are covered in ISO 17248 and ISO 17245, respectively.

If another surface finish is required by the parties involved, the surface finish condition shall be described. Sharp edges of test pieces might give anomalous behaviour. These shall be slightly rounded during the final stages of test piece preparation. The dimensions of the test pieces shall be measured prior to exposure at a minimum of three positions for each dimension with a precision of ±0,02 mm by means of the measuring instruments specified in ISO 3611, ISO 13385-1 and ISO 13385-2. After ultrasonically degreasing in isopropanol or ethanol, the test pieces shall be dried in hot air or in a desiccator. If it is suspected that test pieces might absorb significant amounts of atmospheric contaminants such as water, it is recommended that the cleaned test pieces are stored in a desiccator prior to weighing and exposure. The mass of the test pieces shall be determined prior to exposure. At least two measurements shall be made for each test piece. The difference between the measurements shall not exceed 0,05 mg.

4.2.2 Corrosive deposit

The type of deposit to be used in the test shall be selected in accordance with the environment for which the test is intended. It shall be prepared either by taking ash from actual equipment or by mixing chemicals of reagent grade. The melting temperature of the deposit should be measured in advance. The deposit load applied will depend upon the chemistry of the deposit. Typical levels employed may range from 1 mg/cm 2 for sprayed salt deposits to 30 mg/cm 2 for suspended ash deposits. The deposit can be applied as a solution, as a suspension, or as a dry powder. As a solution the deposit may be sprayed onto the test piece. If this technique is used it is recommended that the test piece be heated, e.g. by a hot plate. For a suspension the corrosive deposit shall be ground in a mortar. It shall then be suspended in a liquid that does not react with the deposit or substrate. The suspension shall be mixed well. The deposit can be applied for instance by dipping or painting. A specified amount shall be applied on the surfaces of interest. Drying is recommended prior to exposure.

ISO 17224:2015 pdf download