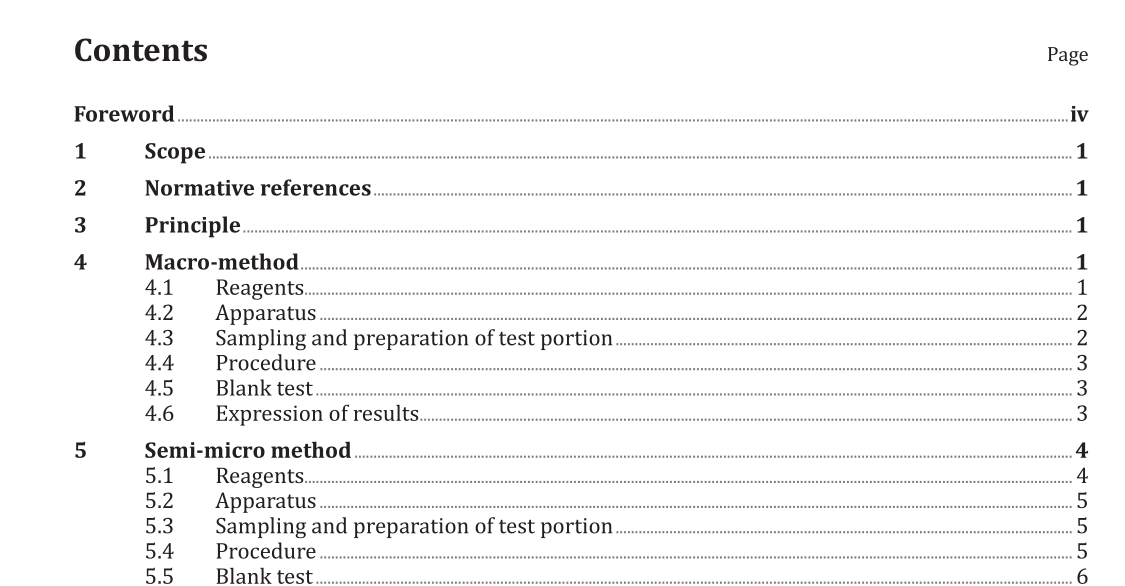

ISO 1656:2014 pdf download.Rubber, raw natural, and rubber latex, natural — Determination of nitrogen content

4.4 Procedure

4.4.1 Cut about 2 g of the rubber or dried latex, weighed to the nearest 0,5 mg, into small pieces and place in the digestion flask (see 4.2). Add about 13 g of the catalyst mixture (4.1.1.1) and 60 cm 3 of the sulfuric acid (4.1.2) or, alternatively, 65 cm 3 of the catalyst solution (4.1.1.2). Mix the contents of the flask by swirling and then boil gently until the solution is clear. Continue boiling for 1 h. NOTE Acidic fumes evolved during digestion will be trapped in an alkaline solution and will be neutralized before being discharged. Allow the digestion flask and its contents to cool to room temperature then cautiously add 200 cm 3 of water and mix by swirling. Place the receiving flask containing the absorbing solution in position, connect the distillation unit, and then slowly add 150 cm 3 of the sodium hydroxide solution (4.1.5) to the digestion flask from a dropping funnel.

4.4.2 Carry out the absorption and titration of the liberated ammonia by the procedure described in 4.4.2.1 or 4.4.2.2. The temperature of the receiving flask shall be maintained below 30 °C to prevent any loss of ammonia. NOTE Ensure proper disposal of the selenium-containing waste in the distillation flask.

4.4.2.1 Place 75 cm 3 of water and, by means of a pipette, 25 cm 3 of the standard volumetric sulfuric acid solution (4.1.3) in the receiving flask of the distillation unit together with two drops of mixed indicator solution (4.1.7). Position the receiving flask so that the end of the delivery tube from the condenser dips below the surface of the absorbing solution. While holding the stopper of the digestion flask in place, thoroughly mix the contents by swirling. Immediately commence distillation and continue at a steady rate until 200 cm 3 of distillate have been collected. If the colour of the indicator changes, it indicates alkalinity of the absorbing solution. Discontinue the determination and repeat the procedure using more sulfuric acid or a smaller test portion. When the distillation is complete (normally, when the volume in the flask reaches about 300 cm 3 ), titrate the contents with the sodium hydroxide solution (4.1.4), reading the burette to the nearest 0,02 cm 3 .

5.4.2.1 Add from the semi-micro burette (5.2.3) to the steamed-out receiver of the distillation apparatus a measured volume of sulfuric acid solution (5.1.3), using at least 5 cm 3 (the exact volume depending on the amount of nitrogen expected), together with two drops of the mixed indicator solution (5.1.7) and about 5 cm 3 of water. Position the receiver so that the end of the delivery tube from the condenser dips below the surface of the acid. It is an advantage to tilt the receiver slightly to gain a greater depth of liquid. Add approximately 15 cm 3 of the sodium hydroxide solution (5.1.4) to the distillation flask by means of a measuring cylinder and pass steam from the generator through the distillation flask for 10 min to 12 min at such a rate that the final volume of liquid in the receiver is about 70 cm 3 . If the colour of the indicator changes, indicating alkalinity of the absorbing solution, discontinue the determination and repeat the procedure using more sulfuric acid or a smaller test portion. When the distillation is complete, lower the receiving flask until the tip of the condenser is above the level of the acid, continue the distillation for another 1 min and then rinse the tip of the condenser tube with a few cubic centimetres of water which shall be collected in the distillate. Immediately titrate the contents of the receiving flask with the sodium hydroxide solution (5.1.5), reading the burette to the nearest 0,02 cm 3 .

ISO 1656:2014 pdf download