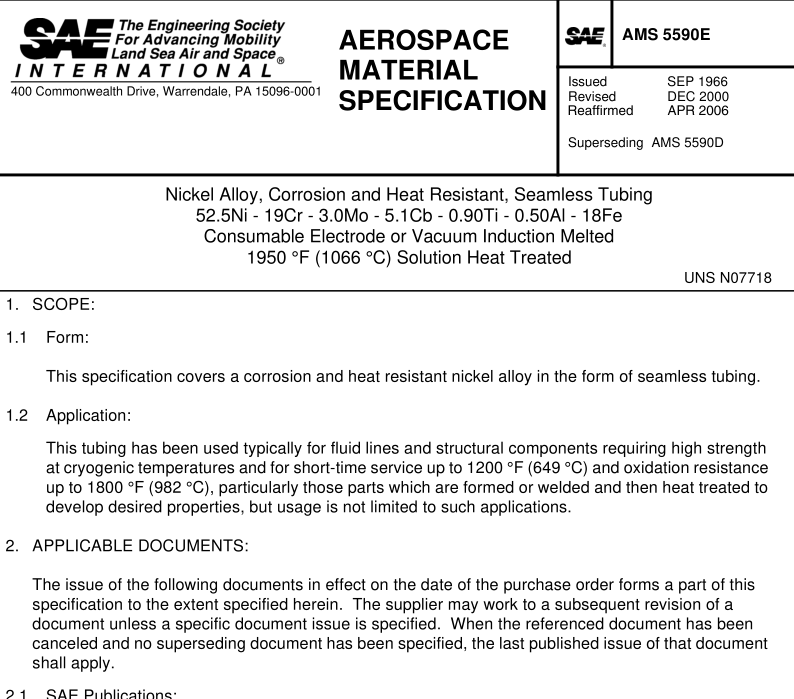

SAE AMS 5590E:2000 pdf download Nickel Alloy, Corrosion and Heat Resistant, Seamless Tubing 52.5Ni – 1 9Cr – 3.0Mo – 5.1 Cb – 0.90Ti – 0.50Al – 1 8Fe Consumable Electrode or Vacuum Induction Melted 1 950 °F (1 066 °C) Solution Heat Treated

1 . SCOPE:

1 .1 Form: This specification covers a corrosion and heat resistant nickel alloy in the form of seamless tubing.

1 .2 Application: This tubing has been used typically for fluid lines and structural components requiring high strength at cryogenic temperatures and for short-time service up to 1 200 °F (649 °C) and oxidation resistance up to 1 800 °F (982 °C), particularly those parts which are formed or welded and then heat treated to develop desired properties, but usage is not limited to such applications.

2. APPLICABLE DOCUMENTS: The issue of the following documents in effect on the date of the purchase order forms a part of this specification to the extent specified herein. The supplier may work to a subsequent revision of a document unless a specific document issue is specified. When the referenced document has been canceled and no superseding document has been specified, the last published issue of that document shall apply.

2.1 SAE Publications:

Available from SAE, 400 Commonwealth Drive, Warrendale, PA 1 5096-0001 .

AMS 2263 Tolerances, Nickel, Nickel Alloy, and Cobalt Alloy Tubing

MAM 2263 Tolerances, Metric, Nickel, Nickel Alloy, and Cobalt Alloy Tubing

AMS 2269 Chemical Check Analysis Limits, Nickel, Nickel Alloys and Cobalt Alloys

AMS 2371 Quality Assurance Sampling and Testing, Corrosion and Heat Resistant Steels and Alloys, Wrought Products and Forging Stock

AMS 2632 Ultrasonic Inspection of Thin Materials, 0.5 Inch (1 3 mm) and Thinner

AMS 2807 Identification, Carbon and Low-Alloy Steels, Corrosion and Heat Resistant Steels and Alloys, Sheet, Strip, Plate, and Aircraft Tubing

2.2ASTM Publications:

Available from ASTM,100 Barr Harbor Drive, West Conshohocken, PA 19428-2959.

ASTME8

Tension Testing of Metallic Materials

ASTM E 8MTension Testing of Metallic Materials (Metric)

ASTME18 Rockwell Hardness and Rockwell Superficial Hardness of Metallic MaterialsASTM E112Determining the Average Grain Size

ASTME 354 Chemical Analysis of High-Temperature,Electrical, Magnetic, and Other Similar

lron,Nickel, and Cobalt Alloys

ASTME426 Electromagnetic (Eddy-Current)Examination of Seamless and Welded Tubular

Products,Austenitic Stainless Steel and Similar Alloys

ASTME 1417Liquid Penetrant Examination

3. TECHNICAL REQUIREMENTS:

3.1 Composition:

Shall conform to the percentages by weight shown in Table 1, determined by wet chemical methodsin accordance with ASTME 354, by spectrochemical methods, or by other analytical methods

acceptable to purchaser.

SAE AMS 5590E:2000 pdf download