ISO 6892-1:2016 pdf download.Metallic materials — Tensile testing — Part 1: Method of test at room temperature

1 Scope

This part of ISO 6892 specifies the method for tensile testing of metallic materials and defines the mechanical properties which can be determined at room temperature.

NOTE Annex A contains further recommendations for computer controlled testing machines.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 7500-1, Metallic materials — Verification of static uniaxial testing machines — Part 1:Tension/compression testing machines — Verification and calibration of the force-measuring system

ISO 9513, Metallic materials — Calibration of extensometer systems used in uniaxial testing

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

NOTE In what follows, the designations “force” and “stress” or “extension”, “percentage extension”, and “strain”,respectively, are used on various occasions (as figure axis labels or in explanations for the determination of different properties). However, for a general description or point on a curve, the designations “force” and “stress” or “extension”, “percentage extension”, and “strain”, respectively, can be interchanged.

3.1 gauge length

length of the parallel portion of the test piece on which elongation is measured at any moment during the test

3.1.1 original gauge length

length between gauge length (3.1) marks on the test piece measured at room temperature before the test

3.1.2 final gauge length after fracture

length between gauge length (3.1) marks on the test piece measured after rupture, at room temperature,the two pieces having been carefully fitted back together so that their axes lie in a straight line

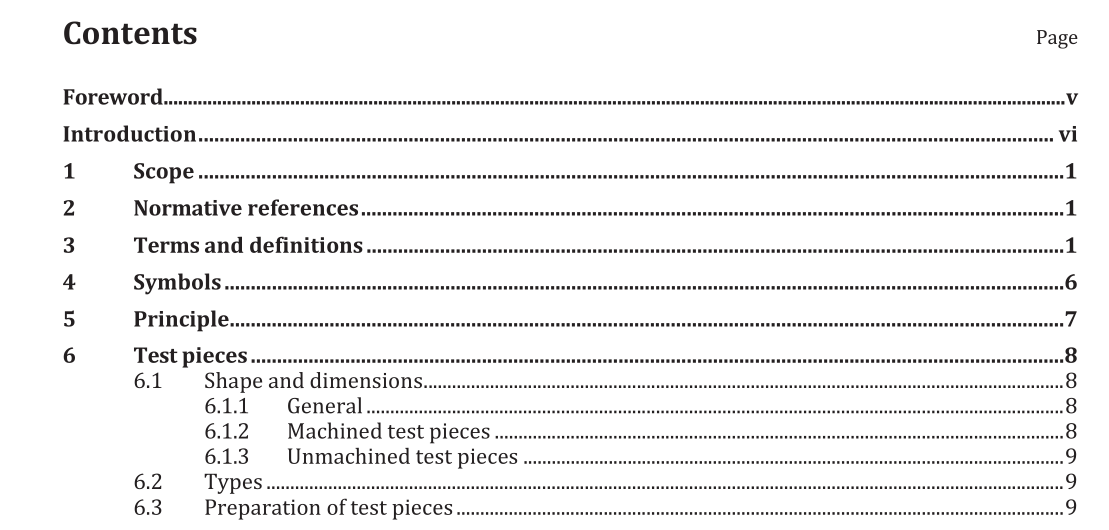

6 Test pieces

6.1 Shape and dimensions

6.1.1 General

The shape and dimensions of the test pieces may be constrained by the shape and dimensions of the metallic product from which the test pieces are taken. The test piece is usually obtained by machining a sample from the product or a pressed blank or casting. However, products of uniform cross-section (sections, bars, wires, etc.) and also as-cast test pieces (i.e. for cast iron and non-ferrous alloys) may be tested without being machined. The cross-section of the test pieces may be circular, square, rectangular, annular or, in special cases, some other uniform cross-section. Preferred test pieces have a direct relationship between the original gauge length, L o , and the original cross-sectional area, S o , expressed by the formula L o = k , where k is a coefficient of proportionality, and are called proportional test pieces. The internationally adopted value for k is 5,65. The original gauge length shall be not less than 15 mm. When the cross-sectional area of the test piece is too small for this requirement to be met with, k,= 6 5 55, a higher value (preferably 11,3) or a non-proportional test piece may be used. NOTE By using an original gauge length smaller than 20 mm, the uncertainty of the result “elongation after fracture” will be increased. For non-proportional test pieces, the original gauge length, L o , is independent of the original cross- sectional area, S o . The dimensional tolerances of the test pieces shall be in accordance with the Annexes B to E (see 6.2).

ISO 6892-1:2016 pdf download