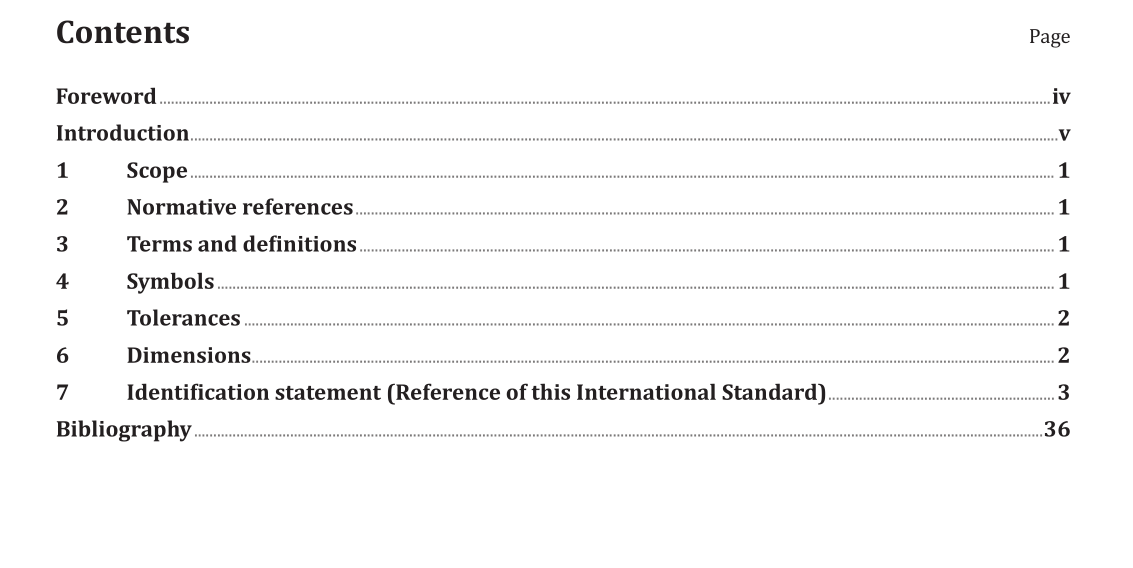

ISO 7368:2016 pdf download.Hydraulic fluid power — Two-port slip-in cartridge valves — Cavities

1 Scope

This document specifies only geometrical data relating to cavities in which two-port hydraulic slip-in cartridge valves are mounted in order to ensure interchangeability.

NOTE For example, this document does not specify rated pressures.

It applies to cavities for two-port hydraulic slip-in cartridge valves which are generally applicable to industrial equipment.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1302, Geometrical Product Specifications (GPS) — Indication of surface texture in technical product documentation

ISO 2768-1, General tolerances — Part 1: Tolerances for linear and angular dimensions without individual tolerance indications

ISO 3601-2, Fluid power systems — O-rings — Part 2: Housing dimensions for general applications

ISO 4287, Geometrical Product Specifications (GPS) — Surface texture: Profile method — Terms, definitions and surface texture parameters

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 5598 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

4 Symbols

a) A, B, X, Y, Z 1 and Z 2 identify ports the operational usage of which, in some cases, may be different from that given in the following examples:

1) A: inlet, service, return corresponding to the placing in the hydraulic circuit;

2) B: inlet, service, return corresponding to the placing in the hydraulic circuit;

3) X: pilot, inlet;

4) Y: pilot, return;

5) Z 1 : supplementary pilot, inlet;

6) Z 2 : supplementary pilot, return;

b) F 1 … F 12 identify threaded holes for fixing screws;

c) G, G 1 and G 2 identify the location of pin holes;

d) D identifies the fixing screw diameter;

e) r max identifies the mounting surface edge radius;

f) R 1 indicates the maximum radius at the bottom of d 1 .

The code system used in this document is defined in ISO 5783.

NOTE Size 15 and size 16 are not yet listed in ISO 5783.

5 Tolerances

The following requirements shall be applied to the sealing and chamfer surfaces, i.e. that area within the chain lines:

— surface roughness (see ISO 3601-2);

— surface roughness, Rz: as indicated on the figures according to ISO 1302 and ISO 4287;

— all non-specified surface finishes: Rz 63;

— surface roughness values are given in micrometres (µm);

— surface flatness: 0,01 mm over a distance of 100 mm (see ISO 3601-2).

The following tolerances shall be complied with along the x, y and z axes with respect to the origin:

— pin holes: ±0,2 mm;

— screw holes: ±0,2 mm;

— port holes: ±0,2 mm;

— general tolerances according to ISO 2768-1 for linear and angular dimensions without tolerances.

As for other dimensions, see Figure 1 to Figure 16.

ISO 7368:2016 pdf download