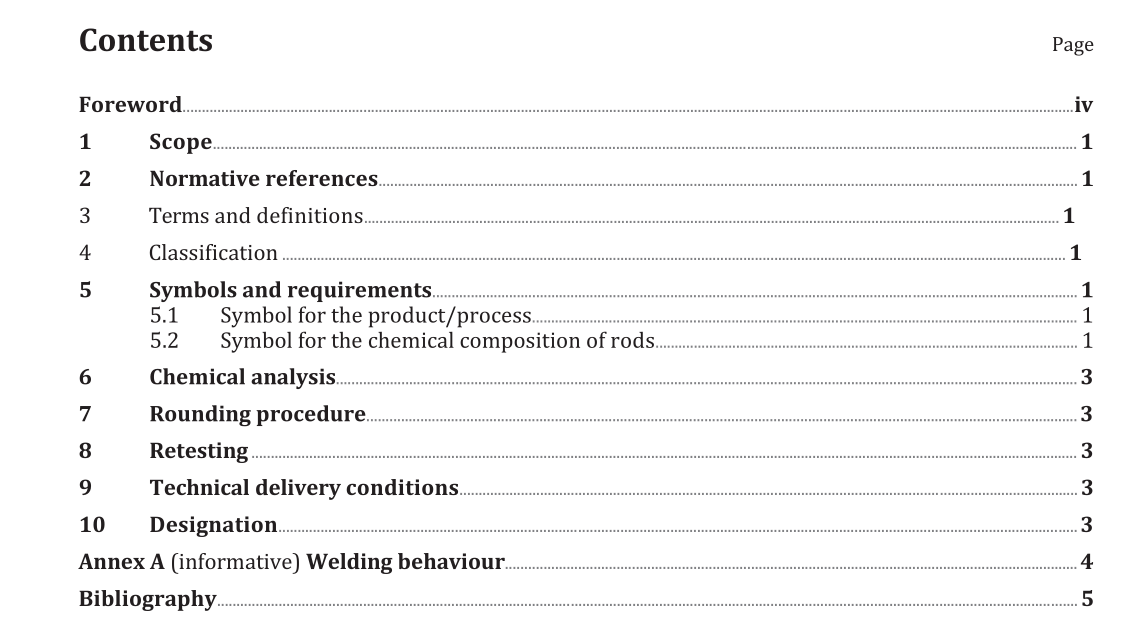

BS ISO 20378:2017 pdf download.Welding consumables — Rods for gas welding of non-alloy and creep-resisting steels — Classification

1 Scope

This document specifies a classification for the designation of rods for gas welding of non‑alloy and creep-resisting steels in terms of the chemical composition of the rod.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 544, Welding consumables — Technical delivery conditions for filler materials and fluxes — Type of product, dimensions, tolerances and markings

ISO 80000-1:2009, Quantities and units — Part 1: General. Corrected by ISO 80000‑1:2009/Cor 1:2011

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at ht tp://www.electropedia.org/

— ISO Online browsing platform: available at ht tp://www.iso.org/obp

4 Classification

A rod shall be classified with the symbol for its chemical composition in accordance with Table 1. Information about welding behaviour is given in Annex A.

The classification is divided into two parts:

a) the first part gives a symbol indicating the product/process to be identified;

b) the second part gives a symbol indicating the chemical composition of the rod.

5 Symbols and requirements

5.1 Symbol for the product/process

The symbol for the rod used in the gas welding process shall be the letter “O”.

5.2 Symbol for the chemical composition of rods

The symbol in Table 1 indicates the chemical composition of the rod, determined under conditions given in Clause 6.

8 Retesting

If any test fails to meet the requirement, that test shall be repeated twice. The results of both retests shall meet the requirement. Specimens for the retest may be taken from the original sample or from a new sample. For chemical analysis, retesting need be only for those specific elements that fail to meet its test requirement. If the results of one or both retests fail to meet the requirement, the material under test shall be considered as not meeting the requirements of this specification for that classification. In the event that, during preparation or after completion of any test, it is clearly determined that prescribed or proper procedures were not followed in preparing the sample or sample(s), or in conducting the tests, the test shall be considered invalid, without regard to whether the test was actually completed, or whether the test results met, or failed to meet, the requirement. That test shall be repeated, following proper prescribed procedures. In this case, the requirement for doubling the number of samples does not apply.

BS ISO 20378:2017 pdf download