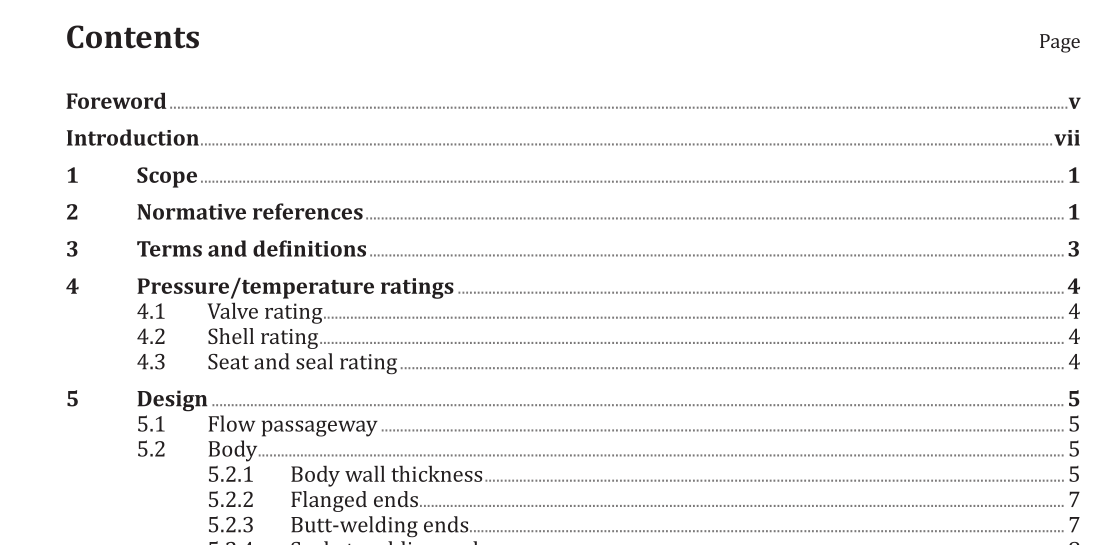

ISO 17292:2015 pdf download.Metal ball valves for petroleum, petrochemical and allied industries

4 Pressure/temperature ratings

4.1 Valve rating

The service pressure/temperature rating applicable to valves specified in this International Standard shall be the lesser of the shell rating (see 4.2) or the seat rating (see 4.3).

4.2 Shell rating

4.2.1 The pressure/temperature ratings applicable to the valve pressure containing shell (the pressure boundary elements, e.g. body, body cap, trunnion cap, cover, body inserts) shall be in accordance with those specified in the pressure/temperature tables of either ASME B16.34, Standard Class for Class- designated valves, or EN 12516-1 for PN-designated valves.

4.2.2 The temperature for a corresponding shell pressure rating is the maximum temperature that is permitted for the pressure containing shell of the valve. In general, this maximum temperature is that of the contained fluid. The use of a pressure rating corresponding to a temperature other than that of the contained fluid is the responsibility of the user. For temperatures below the lowest temperature listed in the pressure/temperature tables (see 4.2.1), the service pressure shall be no greater than the pressure for the lowest listed temperature. Consideration should be given to the loss of ductility and impact strength of many materials at low temperature.

4.3 Seat and seal rating

4.3.1 Non-metallic elements, e.g. seats, seals, or stem seals, may impose restrictions on the applied pressure/temperature rating. Any such restriction shall be shown on the valve identification plate in accordance with 7.4.

4.3.2 The design shall be such that when polytetrafluoroethylene (PTFE), modified PTFE, reinforced PTFE, or modified reinforced PTFE is used for seats, the minimum seat pressure/temperature rating shall as specified in Table 1.

4.3.3 Seat ratings for other seat materials shall be the manufacturer’s standard. Seats made from hard materials such as solid cobalt-chromium alloy, ceramics, or metal seats coated with hard materials such as carbide coatings are also acceptable and shall have seat pressure-temperature ratings per the manufacturer’s standard. The seat pressure/temperature rating shall not exceed that of the valve shell.

5 Design

5.1 Flow passageway

The flow passageway includes the circular seat opening in the ball and the body runs leading thereto. The body runs are the intervening elements that link the seat opening to the end connection, e.g. to the thread end, weld end, or socket end or to the end-flange. Collectively, the flow passageway through the ball and body runs is referred to as the flow passageway. The bore is categorized in this International Standard as full bore, reduced bore, and double reduced bore. The minimum bore for each category shall be such that a hypothetical cylinder having a diameter in accordance with Table 2 can be passed through when the handle or gear operator is moved to the full open position stop.

ISO 17292:2015 pdf download