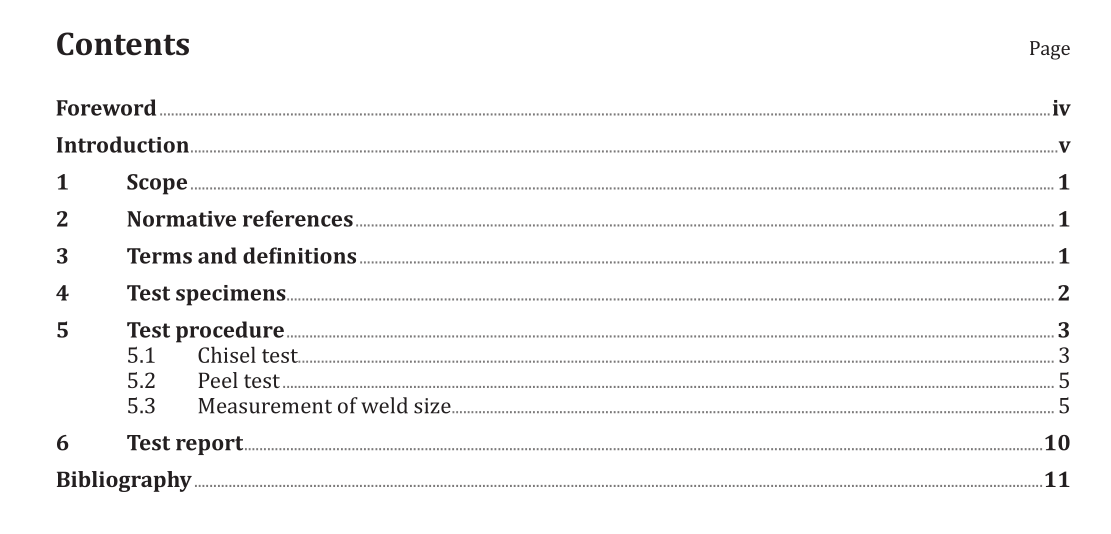

ISO 10447:2015 pdf download,Resistance welding — Testing of welds — Peel and chisel testing of resistance spot and projection welds

1 Scope

This International Standard specifies the procedures and recommended tooling to be used for peel and chisel testing of resistance spot and projection welds. This International Standard applies to welds made in two or more sheets in the thickness range of 0,5 mm to 3,0 mm.

The aim of these tests is to determine

— weld size and failure type when welds are destructively tested, and

— verification of welds by non-destructive chisel tests.

NOTE The preferred method of peel testing seam welds (mechanized peel testing) is covered in ISO 14270.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 14270, Specimen dimensions and procedure for mechanized peel testing resistance spot, seam and embossed projection welds

ISO 17677-1, Resistance welding — Vocabulary — Part 1: Spot, projection and seam welding

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 17677-1 and the following apply.

3.1 chisel test

destructive test with a chisel in which welds are tested by applying a predominantly tensile force that results in stresses primarily normal to the surface of the joint interface

Note 1 to entry: See Figure 1.

3.2 peel test

destructive test in which welds are tested by applying a peel force that results in stresses primarily normal to the surface of the joint interface

Note 1 to entry: See Figure 2a and Figure 2b.

4 Test specimens

When used for quality control in production, tests shall be conducted on actual components or specimens taken from actual components. When used for setting welding parameters, where it is not practical to use actual components, separate welded test pieces may be used. The test pieces shall be produced from the same material used for the component, and welded under conditions adapted to simulate and produce the same required weld quality. The effects of different shunt or impedance conditions should be taken into account when producing the test pieces by inserting sufficient material in the throat of the machine to approximate the magnetic effect of the workpiece under production conditions.

5 Test procedure

5.1 Chisel test

A chisel shall be used to separate the sheets adjacent to the weld under test. Typical chisel designs are shown in Figure 3 and Figure 4. The chisel geometry should be chosen based on the workpiece thickness and geometry, weld diameter, distance between welds, and whether the weld is to be destructively or non-destructively tested (see Table 1). The slot in the chisel shown in Figure 3 is only necessary if the axis of the chisel is placed at the centre of the weld. The chisel should be driven between the sheets manually by a hammer or tool with e.g. pneumatic, electric or hydraulic drive.

ISO 10447:2015 pdf download