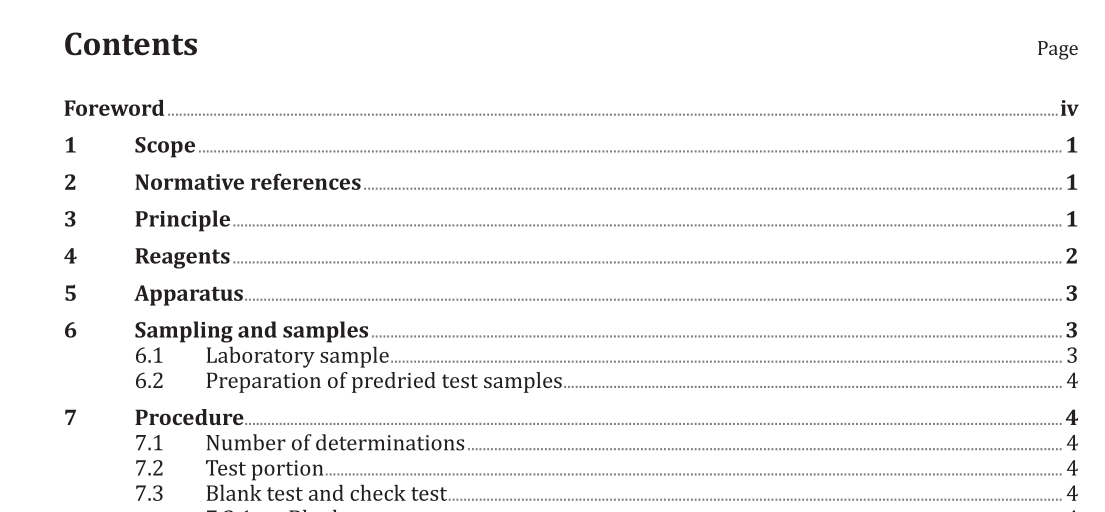

ISO 10204:2015 pdf download.Iron ores — Determination of magnesium — Flame atomic absorption spectrometric method

1 Scope

This International Standard specifies a flame atomic absorption spectrometric method for the determination of the mass fraction of magnesium in iron ores.

This method is applicable to mass fractions of magnesium between 0,010 % and 2,00 % in natural iron ores, iron ore concentrates, and agglomerates, including sinter products.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 648, Laboratory glassware — Single-volume pipettes

ISO 1042, Laboratory glassware — One-mark volumetric flasks

ISO 3082, Iron ores — Sampling and sample preparation procedures

ISO 3696, Water for analytical laboratory use — Specification and test methods

ISO 7764, Iron ores — Preparation of predried test samples for chemical analysis

ISO 9516-1, Iron ores — Determination of various elements by X-ray fluorescence spectrometry — Part 1:Comprehensive procedure

ISO 80000-1:2009, Quantities and units — Part 1: General

ISO Guide 35, Reference materials — General and statistical principles for certification

3 Principle

The test portion is decomposed by the treatment with hydrochloric acid and a small amount of nitric acid and then evaporated to dehydrate silica, followed by dilution and filtration.

The residue is ignited and silica is removed by evaporation with hydrofluoric and sulfuric acids. The residue is fused with sodium carbonate and the cooled melt is dissolved in the filtrate.

The solution obtained is aspirated into the flame of an atomic absorption spectrometer using an air-acetylene burner.

The absorbance values obtained for magnesium are compared with those obtained from calibration solutions.

NOTE A dinitrogen oxide/acetylene flame can be used for the determination, in which case, the sensitivity is decreased by a factor of about 3.

4.8 Background solution

Dissolve 5,0 g pure iron (4.7) in 50 ml of hydrochloric acid (4.2) and oxidize by adding nitric acid (4.4) drop by drop. Evaporate until a syrupy consistency is obtained. Add 20 ml of hydrochloric acid (4.2) and dilute to 200 ml with water. Dissolve 17 g of sodium carbonate (4.1) in water, add carefully to the iron solution, and heat to remove carbon dioxide. Transfer the cooled solution to a 1 000 ml one-mark volumetric flask, dilute to volume with water, and mix.

4.11 Magnesium calibration solutions

Using pipettes, transfer 2,0 ml, 5,0 ml, 10,0 ml, 15,0 ml, and 20,0 ml portions of magnesium standard solution (4.10) to 200 ml volumetric flasks (see next paragraph). Add 6 ml of hydrochloric acid (4.2), 60 ml of background solution (4.8), and 40 ml of lanthanum chloride solution (4.9) to each flask. Dilute the solution to volume with water and mix. Prepare a zero magnesium calibration solution by transferring 60 ml of background solution (4.8) to a 200 ml volumetric flask. Then add 6 ml of hydrochloric acid (4.2) and 40 ml of lanthanum chloride solution (4.9). Dilute the solution to volume with water and mix.

ISO 10204:2015 pdf download