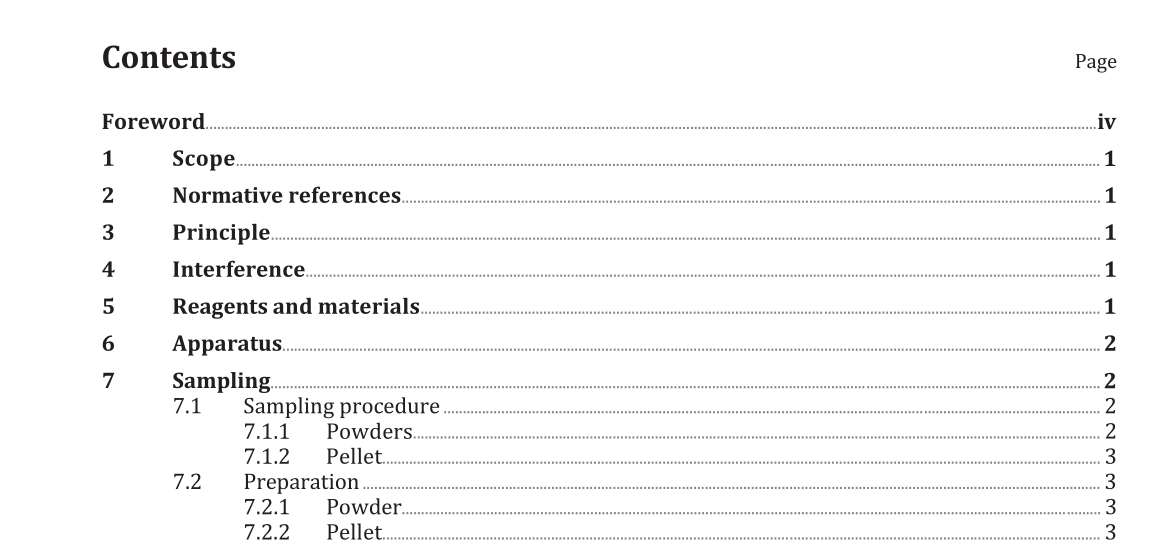

BS ISO 15651:2015 pdf download.Nuclear energy — Determination of total hydrogen content in PuO 2 and UO 2 powders and UO 2 , (U,Gd)O 2 and (U,Pu) O 2 sintered pellets

1 Scope

This International Standard describes a procedure for measuring the total hydrogen content of UO 2 and PuO 2 powders (up to 2 000 µg/g oxide) and of UO 2 and (U,Gd)O 2 and (U,Pu)O 2 pellets (up to 10 µg/g oxide). The total hydrogen content results from adsorbed water, water of crystallization, hydrocarbon,and other hydrogenated compounds which can exist as impurities in the fuel.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO/IEC Guide 98-3:2008, Uncertainty of measurement — Part 3: Guide to the expression of uncertainty in measurement (GUM: 1995)

3 Principle

The total hydrogen content is determined using a hydrogen analyser. The hydrogen analyser is based on the carrier gas method using argon or nitrogen as carrier gas. The samples to be analysed are heated up to a temperature of more than 1 770 °C in a graphite crucible. At that temperature, all volatile components are removed. The hydrogen containing compounds are cracked and released as hydrogen, oxygen,nitrogen, and carbon monoxide. The released gas is purified in the carrier gas stream, for example by oxidation and adsorption columns. The hydrogen is separated by chromatographic means and analysed in a thermal conductivity cell.

4 Interference

The temperature of >1 770 °C should be reached in a short time, within approximately 5 s; if not, the decomposition of the released water to hydrogen and oxygen might not be complete. At temperatures of more than 2 200 °C, carbon dioxide is released because of a reduction of UO 2 by graphite according to the reaction below; carbon dioxide will interfere with the thermal conductivity measurement.

5.2 Calibration gas. If calibration is performed with gas, use Argon or nitrogen with certified hydrogen content or carrier gas mixed with a known amount of hydrogen with a purity of a volume fraction ≥99,999 %.

5.3 Reference material. 1) If calibration or calibration check is performed with a standard material, use a reference material with certified hydrogen content (e.g. titanium or zirconium).

5.4 Copper(II) oxide, CuO purifies the carrier gas (Ar/N 2 ), converting H 2 to H 2 O.

5.5 Absorption media for H 2 O. After converting H 2 to H 2 O (§5.4), anhydrone [Mg(ClO 4 ) 2 ] is used to trap H 2 O.

5.6 Oxidation reagent for CO, Schutze reagent (iodine pentoxide over silica gel) preceded by Hopcalite [manganese oxide/copper(II) oxide] oxidizes CO to CO 2 present in the carrier gas or extracted during measurement.

5.7 Absorption media for CO 2 , sodium hydroxide over clay or equivalent will then absorb the CO 2 .

5.8 Flux reagents for reference material. Tin, copper, or nickel granules are used as flux to accelerate the melting of reference material.

BS ISO 15651:2015 pdf download