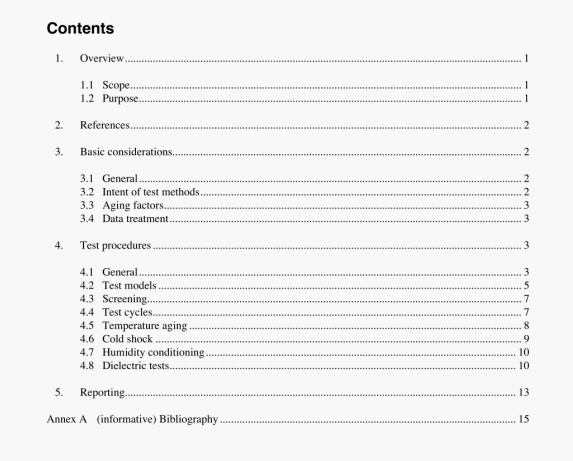

IEEE Std C57.12.60:1998 pdf free download.IEEE Guide forTest Procedures for Thermal Evaluation of Insulation Systems for Solid-Cast and Resin- Encapsulated Power and Distribution Transformers.

a) Full-size transformer coils. Test models may be actual full-size transformers, modified to permit testing of the possible modes of failure. These coils shall be selected to represent the standard full- size coils intended for commercial use. After screening (4.3). the coils will be tested to determine their functional life through the accelerated aging process at elevated temperatures. Since full-size transformer coils arc physically large and extremely expensive to produce, groups of four sample coils shall be tested at no less than three different temperatures. One coil in each set of four shall be designated as the control coil.

b) Representative model coils. Recognizing the high cost of producing and testing full-size transformer coils, representative model coils of the insulation system may be used for this evaluation. In order to provide an accurate evaluation of the thermal aging effects on transformer insulation life, the representative mxlel must accomplish the following:

1) Represent the critical insulation system that (due to thermal degradation) can deteriorate the electrical integrity of the transformer windings.

2) Simulate realistic voltage stresses (impulse or low frequency) for determining the end of functional life of the winding insulation system after the thermal aging process.

In cast coil designs. the turn-to—turn and winding layer-to—layer insulation systems meet the above requirements and, therefore, must be simulated in representative models for establishing the thermal rating of the insulation system.

The characteristics of the cast coil insulation systems that operate in series or in parallel with air gaps (e.g.. axial coil edge-to-ground separation. radial coil-to-coil separation. and axial winding section-to-section separation—see Figure I) depend mainly on air for their insulation strength. These insulation system elements do not degrade significantly by thermal aging of the epoxy insulation. These insulation system elements. therefore. may not he simulated in the representative insulation model.

After screening (4.3). the representative models shall be tested for determining their functional life through the accelerated aging process at elevated temperatures. Since representative models can be made relatively small in size and lower in cost than full-size coils, groups of 12 samples of each shall be tested at no less than three different temperatures. All the samples shall be clearly marked for identification as shown in Table 2.

IEEE Std C57.12.60:1998 pdf free download