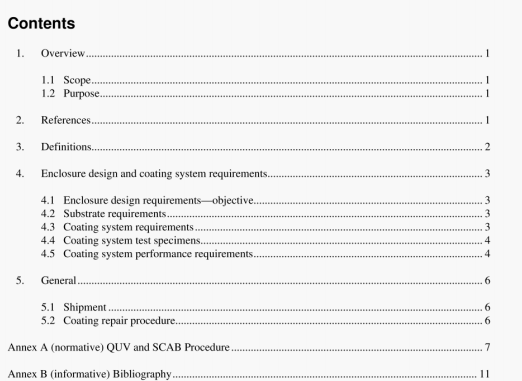

IEEE Std C57.12.31:2002 pdf free download.IEEE Standard for Pole Mounted Equipment- Enclosure Integrity.

4.3.2 Specification of coating characteristics

If more thati one coating system is used tèr different areas of the enclosure, the areas in which each is used shall be identified. The laboratory te performance data of each coaling system shall be identified. The laboratory test performance data of each coating system shall be submitted for approval upon request. This data shall be resubmitted whenever there are changes in the method and/or materials.

4.3.3 Coating touch-up prior to shipment

Touch-up, when required. shall be done at final inspection before any equipment is shipped. In areas where the integrity of the coating system is violaed, the touch-up shall blend smoothly and meet all performance criteria of the original coating.

4.3.4 Enclosure color

Unless OLhe1WIM specified, the topcoat color shall be Munsell number 5B0 7.0/0.4 (ANSI Gray No. 70).

4.4 Coating system test specimens

Test specimens shall consist of panels of the same material composition used in production. Test specimens shall be in accordance with Figure A.l, Figure A.2. Figure A.3, and Figure A.4 as to size and type. Quantity and type of panels in each test are identified under the specific test. All panels shall be cleaned, coated, and cured using the production coating system. Coated test panels shall be conditioned at room temperature and humidity for a minimum of 7 days prior to any testing.

4.5 Coating system performance requirements

4.5.1 Salt spray test

Three coated panels, per Figure A. 1. shall be scribed per ASTM Dl 654-92 and tested for 1000 hours in a 5% salt spray in accordance with ASTM Bl 17-97. The scribe shall be prepared for evaluation using ASTM D1654-92, procedure A, method 2. The scribe shall he divided into 6 mm zones3 and the worst spot in each zone will be evaluated (except the first 6mm of the scribe at each end of the scribe line4). The average of the 14 readings shall be rated per ASTM Dl654-92, Table I. After a rating has been set for each of the three panels, the average rating of the three shall not be less than a 6 rating. The area away from the scribe shall have no blisters.

4.5.2 Cross hatch adhesion test

One coated test panel, per Figure A.2, shall be scribed to bare metal in accordance with ASTM D3359.97. Method A shall he used for films thicker than 0.13 mm, and method B shall be used for films less than or equal to 0.13 minP There shall be 100% adhesion to the substrate and between layer. A rating of 5A for method A and 5B for method B per ASTM D3359-97 is required.

IEEE Std C57.12.31:2002 pdf free download