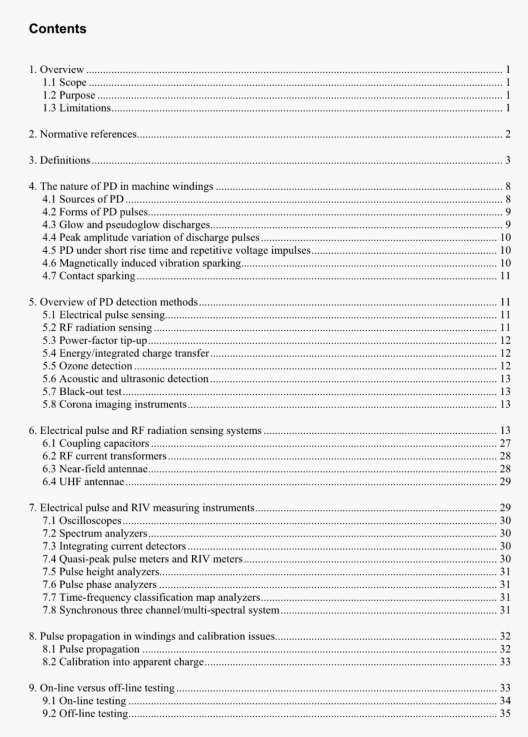

IEEE 1434:2014 pdf free download.IEEE Guide for the Measurement of Partial Discharges in AC Electric Machinery.

5.6 Acoustic and ultrasonic detection

Each creates a small “shock wase” caused by a rapid increase in temperature of the gas in the immediate vicinity of the PD This small shock wave in turn creates acoustical noise, When many PD pulacs arc occurnng on the surfacc of the stator coils, a ‘i’rying bacon” sound results. The acoustical noise occurs in the frequency range of several hundred hertz io over ISO kilt, with most of the acoustical energy occumng around 40 kilt. Directional microphones can be used to measure the PD sound level, as well as to locate where the surface PD may be occurring. Note that the acoustical noise will not be detected if the P1) activity is within the grouridssall unless the activity is especially great. The method can also he used in conjunction with fiberglass rods that act as acoustical was cguides and preside electrical isolation between the component being tested and the detector. Further infomiarion is provided in Zhu et al 1B681.

5.7 Black-out test

A common means of determining the presence and location at surface discharges is to energize the coiLbar or winding under conditions of complete darkness and conduct a visual inspection from a safe distance. The black-out test is primarily useful for detecting and locating surface discharges that involve thc stress control coating, air gaps associated with the end arms of single coils.hars. It can also be used to observe external PD associated with phase-to-phase voltage, or supports associated with the circuit ring bus of VPI’d machine during factory test or on stator models. The black-out test may also he useful for locating girth cracks or slot discharge activity involving individual coils ban. Some disassembly of the machine may be necessaly to facilitate the visual inspection. A 50 lii or 60 lIz variable voltage supply is desirable for applying the test voltage and safety associated with voltage application and working in complete darkness is an issue. A more complete treatment of this subject will be fiund in IEEE Std 1799.

5.8 Corona imaging instruments

An alternative to the blackout test to observe the light emitted by external discharges is to use a corona imaging instrument such as an ultraviolet viewer, The adsantage of this approach is that it can be performed under normal light eanditions which can shorten the test duration and make it easier to locate PD sites To perform the test under normal or reduced lighting is also safer than performing a high voltage test in complete da,kness Because of this IEEE Std 1799 recommends that the test on a stator assembled at site be made with a corona imaging instmment The corona imaging instrument can also be used on single bars or coils or for tests on stator models or VPId stators

6. Electrical pulse and RF radiation sensing systems

A considerable number of different electncal pulse sensing systems arc in usc. The machine design and PD activity may define the type of sensors and the installation required.

IEEE 1434:2014 pdf free download