BS ISO 20977:2018 pdf download.Liming materials — Determination of size distribution by dry and wet sieving

1 Scope

This document specifies two methods for the determination of the particle size distribution of liming materials.

Method A (the dry sieving method) is applicable to all liming materials except wet and paste-like products. Method A is not applicable if blinding, caking, electrostatic charges or agglomeration occur after drying.

Method B (the wet sieving method) is applicable to products which are susceptible to blinding, caking,electrostatic charges or agglomeration after drying. Method B can be used to determine the primary particle size distribution of granulated products. Method B is not applicable to burnt lime and liming materials containing water-soluble constituents.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 565, Test sieves — Metal wire cloth, perforated metal plate and electroformed sheet — Nominal sizes of openings

ISO 3310-1, Test sieves — Technical requirements and testing — Part 1: Test sieves of metal wire cloth

ISO 8397:1988, Solid fertilizers and soil conditioners — Test sieving

ISO 14820-1, Fertilizers and liming materials — Sampling and sample preparation — Part 1: Sampling

EN 12048, Solid fertilisers and liming materials — Determination of moisture content — Gravimetric method by drying at (105 ± 2) °C

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

4 Principle

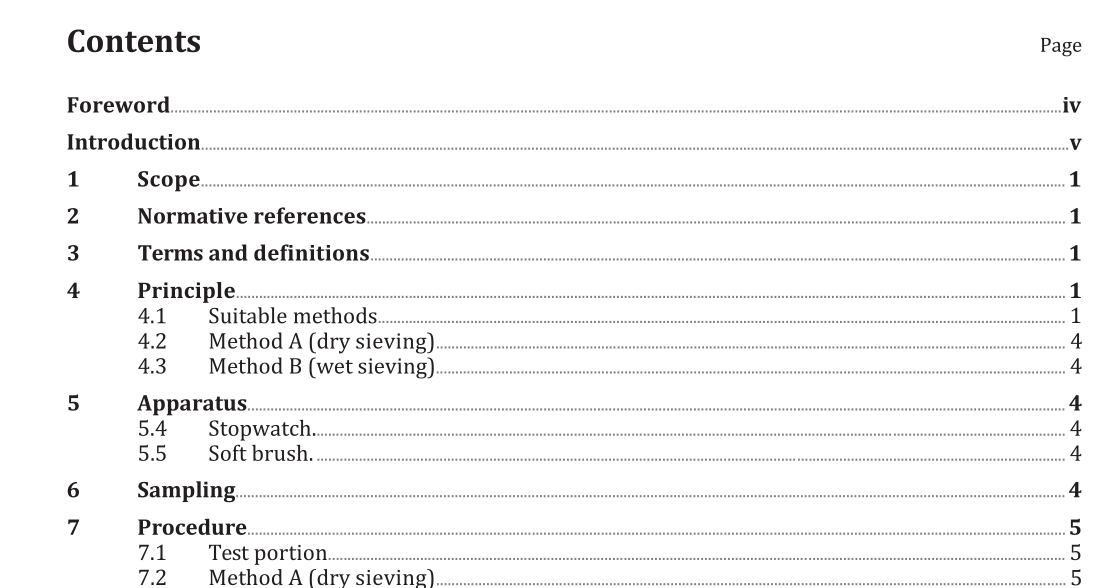

4.1 Suitable methods

Table 1 gives the recommended methods for different liming materials.

In case of different options, see remarks.

7.2.2 Determination

WARNING — When sieving burnt or hydrated lime products, precautions shall be taken to avoid inhalation and skin contact with the product. Operations should be carried out under a fume hood and appropriate gloves should be worn.

7.2.2.1 Carry out at least two single determinations on separate test portions prepared from the same laboratory sample.

7.2.2.2 Select a maximum of seven test sieves (5.3) from the range of principal sizes listed in ISO 565 to cover the range of particle size expected. Assemble the sieves in ascending order of aperture size on top of the receiver. Weigh the test portion (7.1) to the nearest 0,01 g per 100 g of test portion, place it on the top sieve and fit the cover.

7.2.2.3 Place the sieve or the assembled stack of sieves on the mechanical shaker (5.2) and shake for exactly 10 min [use a stopwatch (5.4)].

7.2.2.4 If a stack of sieves is used, remove the sieves from the stack and weigh the quantity retained on each sieve and in the receiver to the nearest 0,01 g. Remove particles caught in the mesh of the sieve by brushing the reverse side of the sieve.

7.2.2.5 If only one sieve is used, discard the undersize fraction that has passed through the sieve. Repeat the sieving process for exactly 1 min. If more than 0,2 g passes through the sieve, repeat the procedure as many times as necessary. Remove particles caught in the mesh of the sieve by brushing the reverse side of the sieve. Weigh the oversize fraction.

BS ISO 20977:2018 pdf download