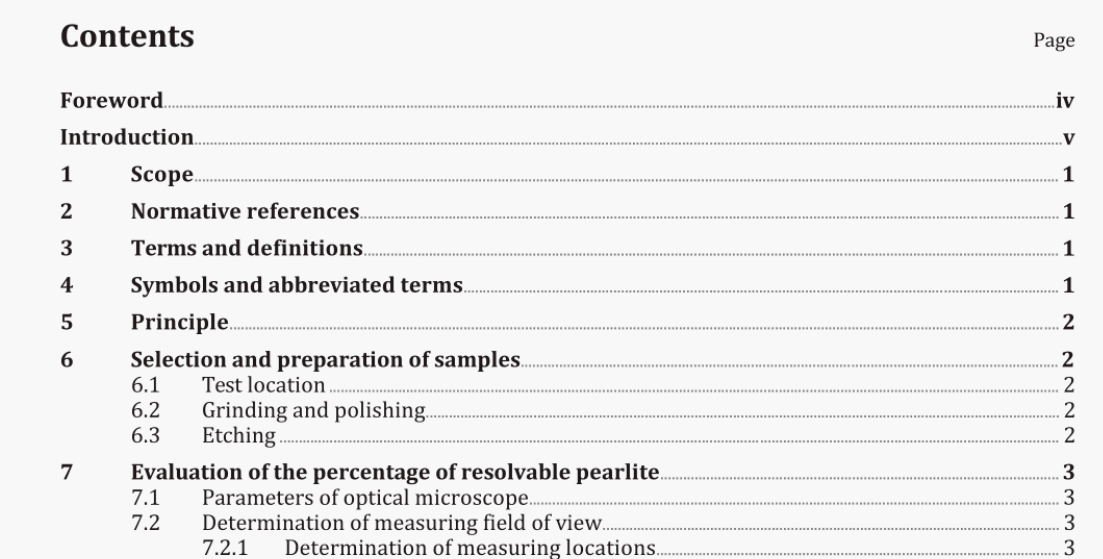

BS ISO 16574:2015 pdf download.Determination of percentage of resolvable pearlite in high carbon steel wire rod

1 Scope

This International Standard defines resolvable pearlite and specifies two methods of determining the percentage of resolvable pearlite.

The methods are applicable for wire rod made from control cooling steel with carbon content greater than 0,65 % C.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 9042, Steels一Manual point counting method for statistically estimating the volume fraction of a constituent with a point grid

ISO 16120-1, Non-alloy steel wire rod for conversion to wire一Part 1: General requirements

3 Terms and definitions

For the purpose of this document, the terms and definitions given in ISO 9042 and ISO 16120-1 apply.

4 Symbols and abbreviated terms

The symbols and corresponding designations are given in Table 1.

5 Principle

5.1 This International Standard defines resolvable pearlite as pearlite where the ferrite and iron carbide lamellae can be observed at 500x magnification under optical microscopy with 0,8 or higher numerical aperture. The light source shall typically be white light, but another light source can be used.

5.2 Resolvable pearlite is revealed by chemical etching of a polished section of the wire rod using an appropriate etchant. The choice of etchant shall refer to 6.3.

5.3 This International Standard specifies two methods of measuring the percentage of resolvable pearlite: manual point count method and automatic image analysis method.

5.3.1 The manual point count method: a grid with a number of regularly arrayed points, which can be a clear plastic test grid or eyepiece reticule, is superimposed over the image, or a projection of the image, produced by a light microscope, and the number of points falling within the constituent of interest are counted and divided by the total number of grid points yielding a point fraction, usually expressed as a percentage, for that field.

5.3.2 Automatic image analysis method: constituents with different microstructure are separated by grey-level intensity differences; for example, pearlites with smaller width between ferrite and iron carbide lamellae are darker than pearlites with bigger width. Thus, the measurement of the content of different constituents can be made on each field by the image analyser on the nature of the discriminated picture point elements in the image.

5.3.3 In case of a dispute, manual point count method shall be the referee method.

BS ISO 16574:2015 pdf download