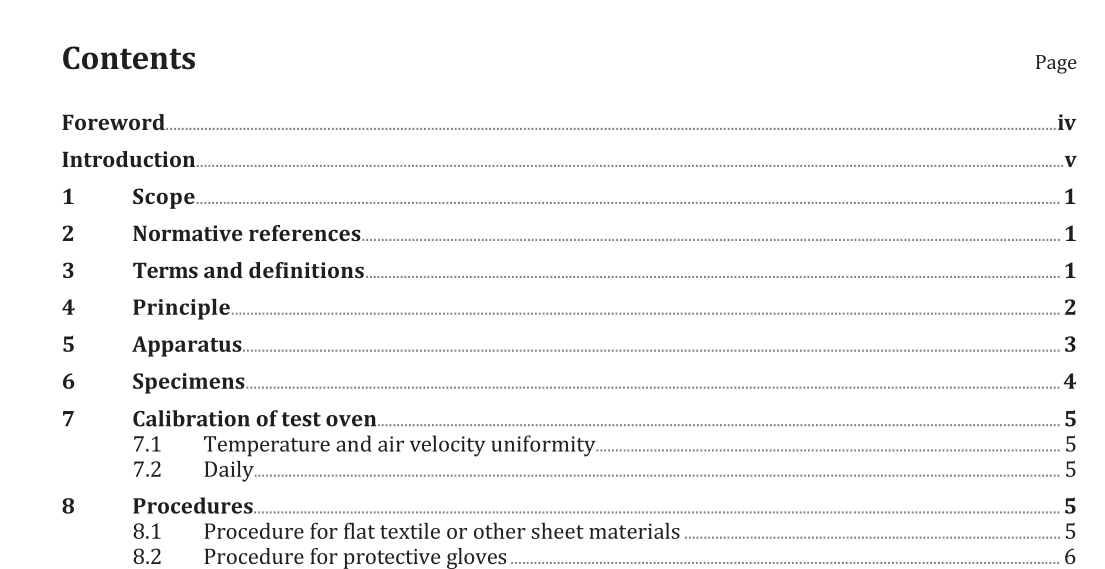

BS ISO 17493:2016 pdf download.Clothing and equipment for protection against heat — Test method for convective heat resistance using a hot air circulating oven

1 Scope

This document describes a test method for evaluating the heat resistance of protective clothing materials or items and equipment when exposed in a hot air circulating oven. The method is intended to evaluate physical changes in a material at a given exposure temperature. Materials are evaluated for defined visible changes including the measurement of shrinkage.Different procedures are provided depending on the type of the protective clothing material or item being tested.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3759, Textiles — Preparation, marking and measuring of fabric specimens and garments in tests for determination of dimensional change

ISO 3873, Industrial safety helmets

ISO 4643:1992, Moulded plastics footwear — Lined or unlined poly(vinyl chloride) boots for general industrial use — Specification

IEC 60584-1, Thermocouples — Part 1: EMF specifications and tolerances

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1 charring

response of the test specimen to heat evidenced by the formation of a carbonaceous residue

3.2 clothing assembly

series of garments arranged in the order as worn

Note 1 to entry: They may contain multilayer materials, material combinations, or a series of separate garments in single layers.

3.3 component assembly

combination of all materials and hardware (3.7) presented exactly as the finished garment construction

4 Principle

Specimens are suspended in a hot air circulating oven for 5 min at the specified test temperature. Any visible observations such as charring, deformation, degradation, delamination, embrittlement, flaking, hole formation, ignition, melting, separating, or splitting of the specimen are recorded. Shrinkage may also be measured. Specimens may also be subject to other property determinations following heat exposure. Observations of degradation, embrittlement, splitting, separating, or flaking can be considered as subjective and should not be used as a pass/fail criteria for a product standard.

The test oven shall be a horizontal flow circulating oven with minimum interior dimensions such that the specimens can be suspended and be at least 50 mm from any interior oven surface or other test specimens. The test oven shall have an airflow rate of 0,5 m/s to 1,5 m/s at the standard temperature and pressure of 20 °C at 1 atm, measured at the centrepoint of the oven. The test oven shall have the following temperature uniformity, when determined according to the procedure specified in A.1The maximum temperature deviation from the specified temperature levels at

— 260 °C for each of the nine thermocouples shall be no greater than 6,5 °C, and

— 180 °C for each of the nine thermocouples shall be no greater than 4,5 °C.

NOTE 1 The above performance requirement for 260 °C is equivalent to the requirement in ASTM F 2894-14 for the maximum temperature deviation specified in ASTM E 145 for IIB oven.

The time constant of the oven, determined according to the procedure of A.2 shall not exceed 660 s.

BS ISO 17493:2016 pdf download