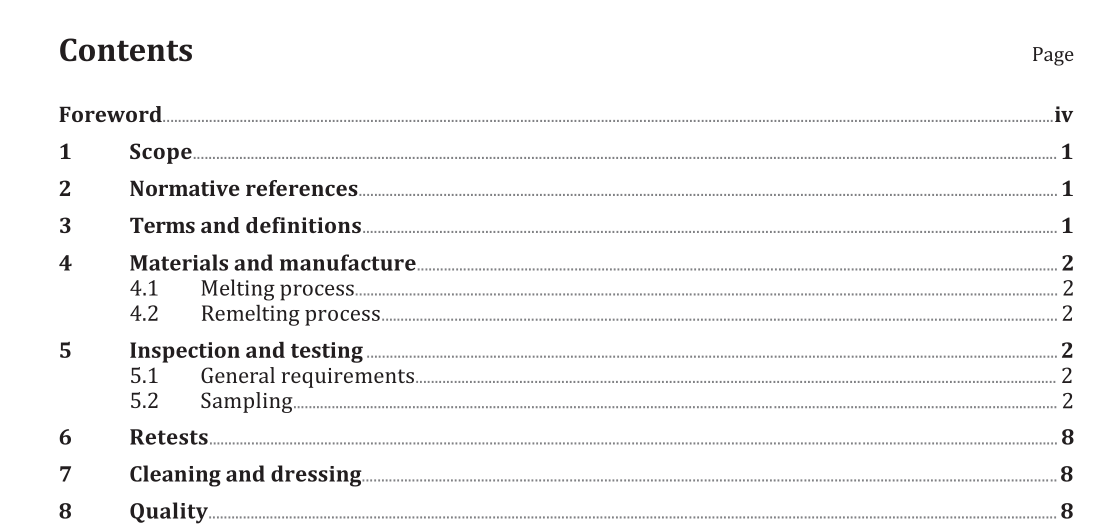

BS ISO 16468:2015 pdf download.Investment castings (steel, nickel alloys and cobalt alloys) — General technical requirements

1 Scope

This International Standard specifies technical requirements for castings (steel, nickel alloys, and cobalt alloys) produced by the investment-casting process. The International Standards specifying metallurgical material requirements for steel, nickel alloy, and cobalt alloy casting grades are listed in the Bibliography. The requirements stated in this International Standard form an integral part of the material specification. In cases of conflict, the requirements of this specification take precedence over the individual material specification requirements.

4 Materials and manufacture

4.1 Melting process

Primary heats shall be made by the electric furnace process, with or without separate refining, such as argon-oxygen-decarburization (AOD), vacuum-oxygen-decarburization (VOD), vacuum-induction- melting (VIM), etc., unless otherwise specified in the individual specification or agreed upon between the purchaser and manufacturer. Primary heats may be used directly for producing castings or converted into ingot, bar, shot, or other suitable form, for later remelting as a sub-heat.

4.2 Remelting process

Sub-heats shall be produced from primary-heat metal in suitable batch sizes by an electric induction furnace, with or without atmosphere protection, such as vacuum or inert gas, unless otherwise specified in the individual specification or agreed upon between the purchaser and manufacturer. Revert (gates, sprues, risers, and rejected castings) shall not be remelted except in primary heats. Additions of up to 5 %, by mass, are permitted for compositional adjustments and deoxidation.

5 Inspection and testing

5.1 General requirements

The general requirements for inspection and testing shall be in accordance with ISO 4990, except as described in 5.2.

5.2 Sampling

5.2.1 If castings are poured directly from one or more primary heats, then the samples for chemical and other required testing shall also be poured directly from each of the primary heats.

5.2.2 Unless otherwise specified by the purchaser, test blocks may be taken from castings, may be cast integrally with the castings, or may be cast in separate moulds of the same type and materials as those used for the castings. Samples for the determination of the chemical composition may be cast in other types of mould.

5.2.3 If castings are poured from a sub-heat, then the samples for chemical and other required tests shall also be poured from a sub-heat of the same primary melt, but not necessarily from the same sub-melt as the castings. The sub-melt used for the test samples shall be produced using the same practices and additions as used for the castings.

BS ISO 16468:2015 pdf download