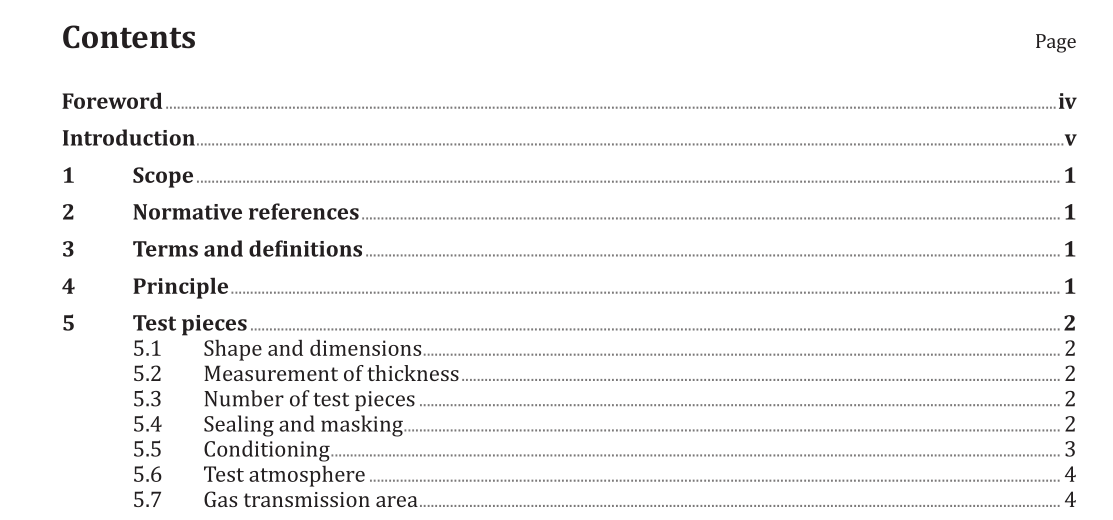

ISO 7229:2015 pdf download.Rubber- or plastics-coated fabrics — Measurement of gas permeability

1 Scope

This International Standard specifies two methods for measuring gas transmission through rubber- or plastics-coated fabrics, a property known as permeability.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 2231, Rubber- or plastics-coated fabrics — Standard atmospheres for conditioning and testing

ISO 2286-3, Rubber- or plastics-coated fabrics — Determination of roll characteristics — Part 3: Methods for determination of thickness

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 gas transmission rate

volume of test gas passing through a test piece per unit area, per unit time with unit partial-pressure difference between the two sides of the test piece

3.2 gas permeability coefficient

volume of test gas passing through a test piece of unit thickness, per unit area, per unit time with unit partial-pressure difference between the two sides of the test piece

3.3 gas transmission curve

in the pressure sensor method, curve plotted against time, of the pressure change on the low pressure side of the test cell until gas transmission reaches a steady state after starting the test

Note 1 to entry: See Figure 3.

4 Principle

A test piece is placed between two parts of a hermetically sealed measurement cell. Each part of the cell is vacuumed, then one part is filled with test gas to a certain pressure level. The quantity of gas that permeates through the test piece to the lower pressure side is measured and determined by a pressure sensor or by a gas chromatograph. In the gas chromatography method, measurement condition using equal pressure between two parts of the cell divided by the test piece is given for information in Annex A.

5 Test pieces

5.1 Shape and dimensions

The test piece shall be of uniform shape and have a thickness of more than 0,10 mm and less than 4,00 mm. When using test pieces other than this, the thickness shall be agreed between the interested parties. The test piece shall be large enough to cover the full area of the test cell.

5.2 Measurement of thickness

Measure the thickness of the test piece at five or more points including the centre part of the gas transmission area to the nearest 0,01 mm in accordance with ISO 2286-3 and take the arithmetic mean.

5.3 Number of test pieces

Three or more test pieces shall be used.

5.4 Sealing and masking

A substrate generally passes gas much more easily than coating materials, and even after the test piece is fixed in the cell, the test gas permeated through the coating material may leak out of the cell through the substrate. Cross section cut at the edge around the test piece shall be sealed or masked with wax or a solid type of adhesive which shall not cause any crack nor affect the gas permeability of the test piece during the test.

When a test piece of single-faced coated fabric is used, the surface of the fabric substrate outside the gas permeability measurement area shall be masked besides the edge as shown in Figure 1.

ISO 7229:2015 pdf download