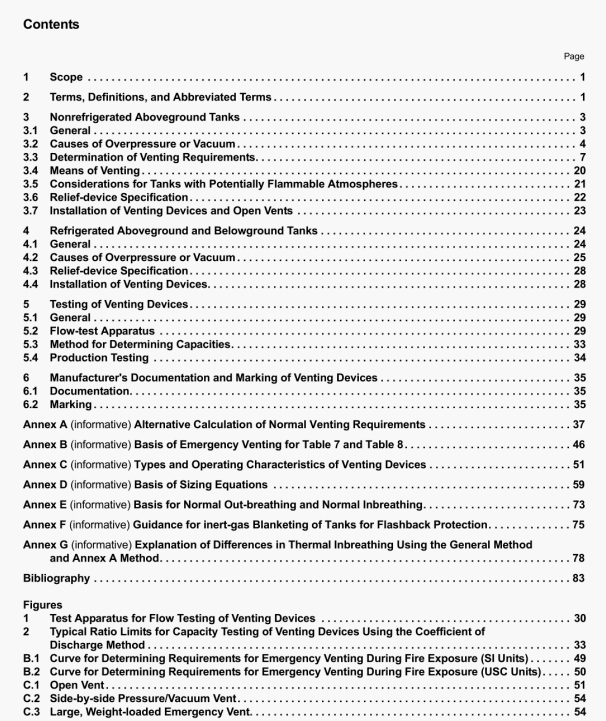

API St 2000:2014 pdf download.Venting Atmospheric and Low-pressure Storage Tanks.

3.3.3.3.5 Credit may be taken for the venting capacity provided by the device installed for normal venting, since the normal thermal effect can be disregarded during a fire. Also, it can be assumed that there is no liquid movement into the tank during fire exposure.

3.3.3.3.6 If normal venting devices have inadequate capacity, additional emergency venting devices of the type described in 3.4.2 Shall be provided so that the total venting capacity is at least equivalent to that required by Table 5 or Table 6 or by Equation (14) or Equation (15).

3.3.3.3.7 The total venting capacity shall be based on the pressure indicated in 36.2.

3.4 Means of Venting

3.4.1 Normal Venting

3.4.1.1 General

Normal venting for pressure and vacuum shall be accomplished by a PV valve with or without a flame- arresting device or by an open vent with or without a flame-arresting device.

Protect atmospheric storage tanks against flame transmission from outside the tank if

the stored liquid has a low flash point, i.e. less than 60 C (140 °F) or in accordance with the applicable regulations. whichever is higher: or

— the storage temperature can exceed the flash point: or

— the tank can otherwise contain a flammable vapor space,

See 3.5 for design considerations for tanks that have potentially flammable atmospheres. A discussion of the types and operating characteristics of venting devices can be found In Annex C.

Relief devices equipped with a weight-lever mechanism for adjusting the set pressure, and nonreclosing relief devices are not recommended for normal venting.

3.4.1.2 PressurelVacuum Valves

To avoid product loss, PV valves are recommended for use on atmospheric storage tanks.

3.4.1.3 Open Vents

If open vents are selected to provide venting capacity for tanks that can contain a flammable vapor space a defined in 3.4.1.1. a flame-arresting device should be used. Open vents without a flame.arresting device may be used for tanks that do not contain a flammable vapor space-

In the case of viscous oils, such as cutback and penetration-grade asphalts, where the danger of tank collapse resulting from sticking pallets or from plugging of flame arresters is greater than the possibility of flame transmission into the tank, open vents may be used as an exception to the requirements of 3.4.1.1; or heat traced vents that ensure that the vapor temperature stays above the dew point may be used.

In areas with strict fugitive emissions regulations, open vents might not be acceptable and vent-device selection should consider the maximum leakage requirements dunng periods of normal tank operation.

3.4.2 Emergency Venting

Emergency venting may be accomplished by the use of the following.

API St 2000:2014 pdf download