API RP 2201:2003 pdf download.Safe Hot Tapping Practices in the Petroleum and Petrochemical lndustries.

4.1 JOB ANALYSIS

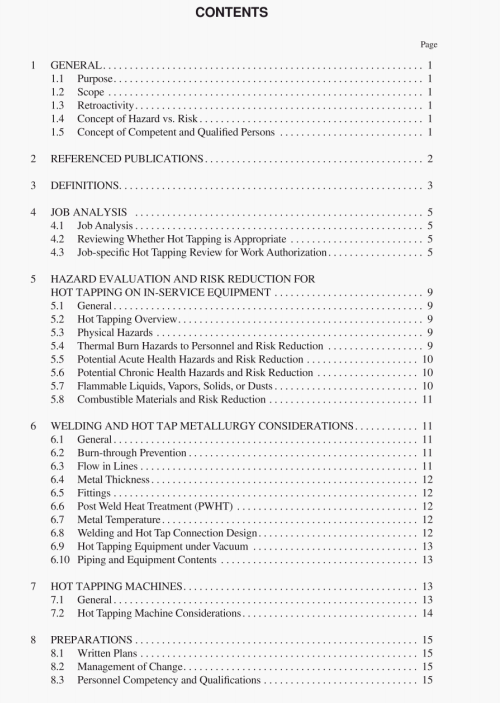

The first step in the hot tapping work process is establishing what needs to be accomplished, how the associated work is to be done, and whether hot tapping is appropriate. The general review process is shown in Figure I. It is important to recognize that hot lapping “by definition” involves hot work on equipment in service. A work scope analysis should be perlonned to determine if alternates to hot tapping exist within reasonable engineering and economic bounds, and whether hot tapping is appropriate (see 4.2).

If, after review, hot tapping is indeed required, the fbllowing approach conforms o good practice and regulatory requirements:

a. Since the work cannot he moved, a review shall determine whether fire haards in the vicinity can he moved to a safe place.

h. Essentially the decision of who is a “competent person” becomes a performance oriented management decision, evaluating varied skills and knowledge for each category.

c. All precautions used for hot work should be followed.

Since hot tapping work can not be done except by performing hot work in place, the work area and each activity should be closely analyzed for hazards, such as the potential hazards discussed in this publication or on the MSDSS relevant to the materials involved (see Section 5). Along with the safeguards in step “c” above this should minimize the risk that hot work may provide a source of personnel exposure or ignition hazards which could lead to a fire or explosion. The consequences of each hazard should be carefully weighed along with unexpected conditions that might occur during hot work.

Contingency plans should be put into place for fire lighting. personnel evacuation, andior alternate methods (such as changes in plant operations) to finish the hot work without incident. Appendix D provides an example of a hot lap emergency action contingency plan.

The example flow chart in Figure 2 shows some of the thought required in making the decision that use of hot tapping is appropriate. OSHA 1910.147 “Control of Hazardous Energy” (LockoutlTagout) provides a specific exemption for performing hot tapping, with several criteria which must be met to satisfy that this is both needed and safe. These criteria are:

a. continuity of service is essential:

b. shutdown of the system is impractical:

c. documented procedures are followed;

d. special equipment is used which will provide proven

effective protection for employees.

As indicated in Figure 2, if all four of these criteria cannot be met then hot tapping should not he done and the work must he performed in conformance with the requirements of the OSHA LockoutfTagout regulation. For work on equipment subject to other regulations (federal or state OSHA Process Safety or DOT) there may well he other regulatory requirements.

API RP 2201:2003 pdf download