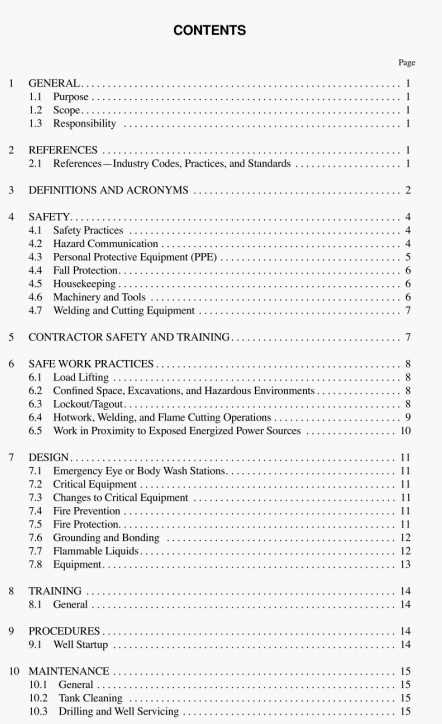

API RP 74:2001 pdf download.Recommended Practice for Occupational Safety for Onshore Oiland Gas Production Operation.

4.7 WELDING AND CUTTiNG EQUIPMENT

4.7.1 Apparatus such as torches. regulators. hoses and arc welding machines shall be in good operating condition and repair. Only approved oxygen and acetylene cylinders shall be used.

4.7.2 Oxygen and acetylene torches shall be equipped with (1 ash-hack arrestors.

4.7.3 All cylinders shall be equipped with a valve protection cap, a collar, or recess to protect the valve. Valve caps should be in place except when cylinders are connected for

4.7.4 Cylinders should be stored in assigned places and shall be secured to prevent accidental overturning.

4.7.5 Cylinders should not be kept in unvcntilatcd enclosures, such as lockers and cupboards.

4.7.6 Oxygen cylinders in storage shall be separated from fuel gas cylinders or combustible materials a minimum distance of 20 ft (6.1 m) or by a noncombustible barrier at least 5 ft(l.5 m)high.

4.7.7 Acetylene cylinders shall be stored valve end up with protective caps aflixed and properly secured. When a job using acetylene devices is completed or prior to transporting acetylene cylinders, the valve on the acetylene cylinder shall he closed and pressure on the hoses bled to rem.

4.7.8 When transporting cylinders by a crane or derrick, a cradle, bin, or other suitable platform should be used. Slings alone shall not be used on a cylinder being transported or lifted. Also, cylinders should not be dropped, struck, or permitted to strike each other.

4.7.9 On arc welding machines, the control apparaWs shall be enclosed except for the operating wheels, levers, or handles.

4.7.10 Input power terminals, top charge devices, and eketrically energized metal parts shall be completely enclosed and accessible only by means of tools.

4.7.11 Terminals from welding leads shall be protected

1mm accidental contact by personnel or metal objcct&

4.7.12 The frame or case of an electrically dnven arc welding machine shall be grounded.

4.7.13 Cables with splices within 10 ft (3.1 m) of the rod bolder shall not be used. The welder should not coil or loop welding electrode cables around parts of his body.

Contractors shall train their personnel in the work practices necessary to perform their jobs in a safe manner. The training provided to contract personnel should include applicable site- specific safety procedures and rules pertaining to the facility and the applicable provisions of emergency action plans. This section applies to Contractors performing operating duties. maintenance or repair. turnaround. major renovation, or specialty work at the facility. Ezccpt for transportation safety orientation. emergency evacuation training, and other applicable safety training, this paragraph does not apply to contractors providing incidental services that do not influence operation of the facility, such as. janitorial work. food and drink services. laundry. delivery, other supply services. etc.

The operator should verify contractor training utiliiing a variety of methods, which may include audits of the contractor’s safety training programs: worksitc checks of individual contractor employees’ training: and operator observation of contractor work performance.

A major step in achieving acceptable contractor performance is selecting a safe contractor. Therefore, it is appropnate for operators to request that contractors submit specific performance information in their contract response proposals. For example. such information might include.

API RP 74:2001 pdf download