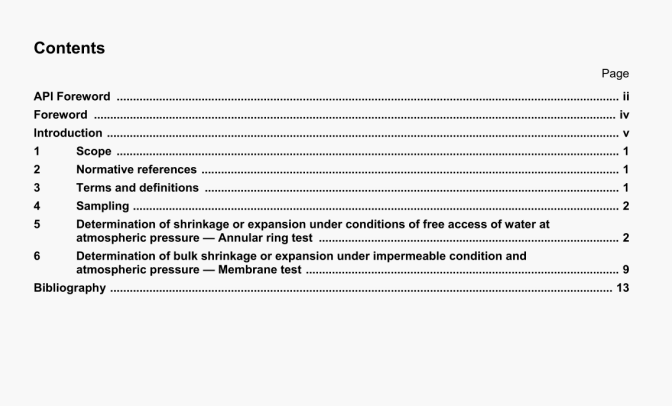

API RP 10B-5:2005 pdf download.Recommended Practice on Determination of Shrinkage and Expansion of Well Cement Formulations at Atmospheric Pressure.

5.2.3 Cooling bath

The cooling-bath dimensions shall be such that the specimen to be cooled from the curing temperature can be

completely submerged in water maintained at 27 C ± 3 C (80 F -t- 5 CF).

5.2.4 Temperature measunng system

The temperature-measuring system shall be calibrated to an accuracy of ± 1 C (±2 F). Calibration shall be no less frequent than monthly. The procedure described In ISO 10426-2:2003, Annex A, is commonly used.

5.2.4.1 Thermometer

A thermometer with a range includIng 21 °C to 100 ‘C (70 F to 212 ‘F) with minimum scale divisions not

exceeding I ‘C (2 ‘F) should be used.

5.2.4.2 Thermocouple

A thermocouple system with the appropnate range should be used.

5.2.5 Conslstometer

The atmospheric-pressure consistometer shall be used for stirring and conditioning the cement slurry. The consistometer consists of a rotating cylindrical slurry container, equipped with an essentially stationary paddle assembly, in a temperature-controlled liquid bath. The consistometer shall be capable of maintaining the temperature of the bath within ± 2 ‘C (± 3 F) of the test temperature and of rotating the slurry container at a speed of 2,5 rls ± 0.25 r/s (150 rpm ± 15 rpm) during the stirring and conditioning period for the slurry. The paddle and all parts of the slurry container exposed to the slurry shall be constructed of con-asian-resistant materials (see ISO 10426-1:2000).

5.3 Procedure

5.3.1 PreparatIon of the mould

The assembled moulds shall be watertight to avoid leakage. The interior faces of the moulds and contact surfaces of the plates may be lightly coated with a release agent. Alternatively, the interior faces of the moulds and contact surfaces of the plates may be left clean and dry. In the case of a shrinkage test, place the spacer block Inside the split of the outer ring. Prepare the mould as follows.

a) Clean the mould thoroughly.

b) Place a bead of grease on the upper and lower plates where the inner stationary ring and the outer expandable ring touch.

C) If desired, apply a very thin film of light mineral oil to the lnnec and outer rings and to the surface of the top and bottom covers that will contact the cement.

d) With the top cover inverted, place the inner and outer flngs on the top cover.

e) Place the bottom cover over the inner and outer rings.

f) Insert the bolt into the centre hole and tighten the bolt to hold the mould together.

g) Verify that the expandable outer ring rotates freely and place the big hole adjacent to the split (Figure 9).

h) Place a small amount of high-temperature grease between the split in the outer ring; the grease will seal the split and prevent the slurry from leaking before it sets.

i) To test for shrinkage, coat a spacer block with grease and place the block with the small side between the split in the outer expandable ring; see Figures 5 and 6.

API RP 10B-5:2005 pdf download