API RP 520-2:2003 pdf download.Sizing,Selection, and lnstallation of Pressure-Relieving Devices in Refineries Part ll—Installation.

A rupture disk dcvicc may bc used as the soic pressure- relief device, or it may be installed between a pressure-relief valve and the vessel or on the downstream sidc of a pressure- relief valve (see Figure 8).

When a rupture disk device is used between the pressure- relief valve and the protected vessel, the space between the rupture disk and the pressure-relief valve shall have a free vent, pressure gauge. trycock. or other suitable telltale indicator. A non-vented space with a pressure gage without alamis or other indication devices is not recommended as a suitable telltale indicator. Users are warned that a rupture disk will not burst in tolerance if back pressure builds up in a non-vented space between (he rUpture disk and the pressure-relief valve. which will occur should leakage develop in the rUpture disk due to corrosion or other cause. Only non-fragmenting nipture disk devices may be used beneath a pressure-relief valve.

Rupture disks may not be available in all sites at lower pressures: therefore, for these low-pressure applications the available rupture disk may have to be larger than the nominal size of the inlet piping and pressure-relief valve.

Refer to API RP 520, Part I for additional information related to the combination capacity factor when a rupture disk is installed in combination with a pressure-relief valve.

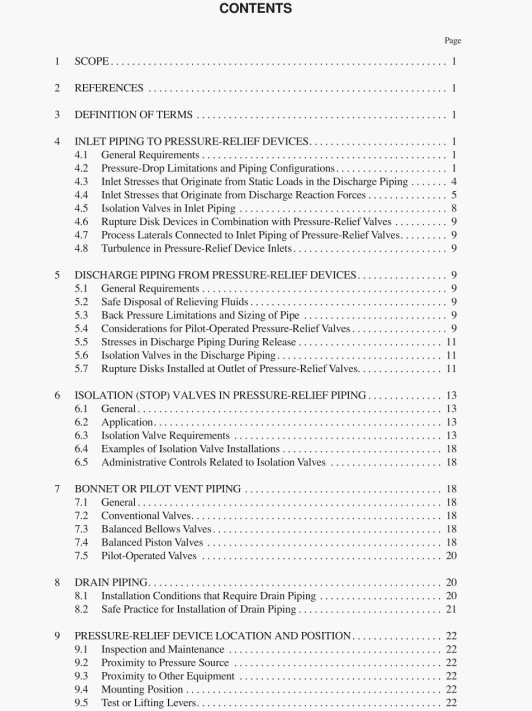

47 PROCESS LATERALS CONNECTED TO INLET PIPING OF PRESSURE-RELIEF VALVES

Process laterals should generally not he connected to the inlet piping of pressure-relief valves (see Figure 9). Esceptions should be analyzed carefully to ensure that the allowable pressure drop at the inlet of the pressure-relief valve is not esceeded under simLiltaneous conditions of rated flow through the pressure-relief valve and masiniLnu possible flow through the process lateral.

4.8 TURBULENCE IN PRESSURE-RELIEF DEVICE INLETS

See 9.3 for information regarding the effects of turbulence on pressure-relief valves.

5 Discharge Piping From Pressure-Relief Devices

5.1 GENERAL REQUIREMENTS

For general requirements for discharge piping. sec Figures l.2,7,and 10.

The discharge piping installation must provide for proper pressure-relief device perfonnance and adequate drainage (free-draining systems are preferred—see Section 8). Consideration should be given to the type of discharge system used, the back pressure on the pressure-relief device. and the set-pressure relationship of the pressure-relief deices in the system.

API RP 520-2:2003 pdf download