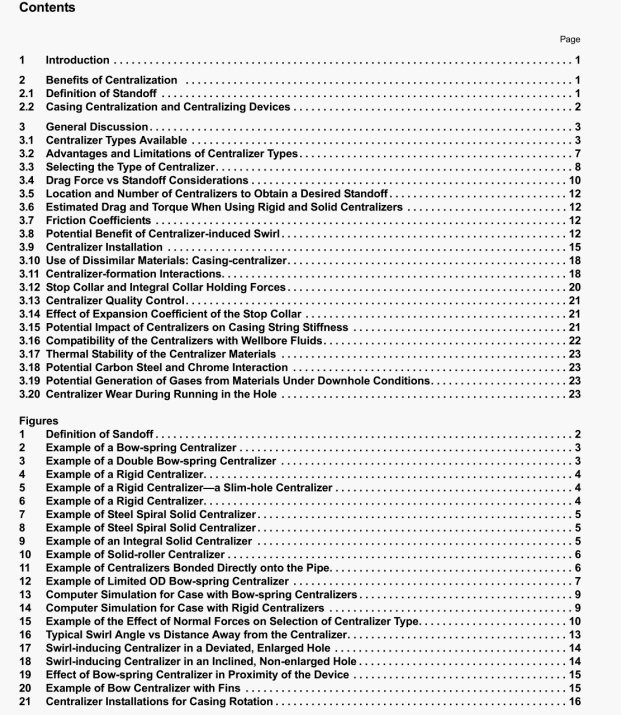

API TR 10TR4:2008 pdf download.Selection of Centralizers for Primary Cementing Operations.

2.2 Casing Centralization and Centralizing Devices

Casing centralization requires mechanical devices (centralizers) to keep the casing away from me wellbore and/or from the cased sections of the well.

Significant issues include:

1. the centralizer must provide enough load support to overcome the normal forces tending to lay the casing against the formation wall, particularly In deviated holes, horizontal holes and through doglegs;

2. enough centralizers should be used to provide good casing centralization over the needed intervals (including at points between the centralizers);

3. it is normally assumed (however not always the case) that the formation can provide enough support for the tools (minimum centralizer embedment).

3 General Discussion

3.1 Centralizer Types Available

The industry has developed three main types of centralizers: bow-spring, rigid, and solid.

3.1.1 Bow-spring Centralizer

The bow-spring centralizer is composed of flexible spring bows (heat-treated steel springs) attached to two collars. By design the bows are flexible enough to allow passage of the centralizer through restrictions but are also expected to provide standoff in enlarged hole sections. The springs come In various shapes and dimensions. The uncompressed outside diameter (00) of a bow-spring centralizer may be much larger than the nominal hole (bit) diameter: thus, this type of centralizer can potentially centraliz& the pipe in moderately washed-out zones. Double- bow centralizers are also available. The double-bow centralizers can provide good restoring forces with low starling and running forces, Double-bow centralizers have a lesser maximum 00 than conventional bow-spring centralizers and might sacrifice standoff in enlarged holes. Double-bow centralizers may also be considered semi-rigid, as will be discussed later in this document.

API TR 10TR4:2008 pdf download