SAE AS 1860A:2002 pdf download NUT, SLEEVE COUPLING, TUBE REDUCER, FLARELESS

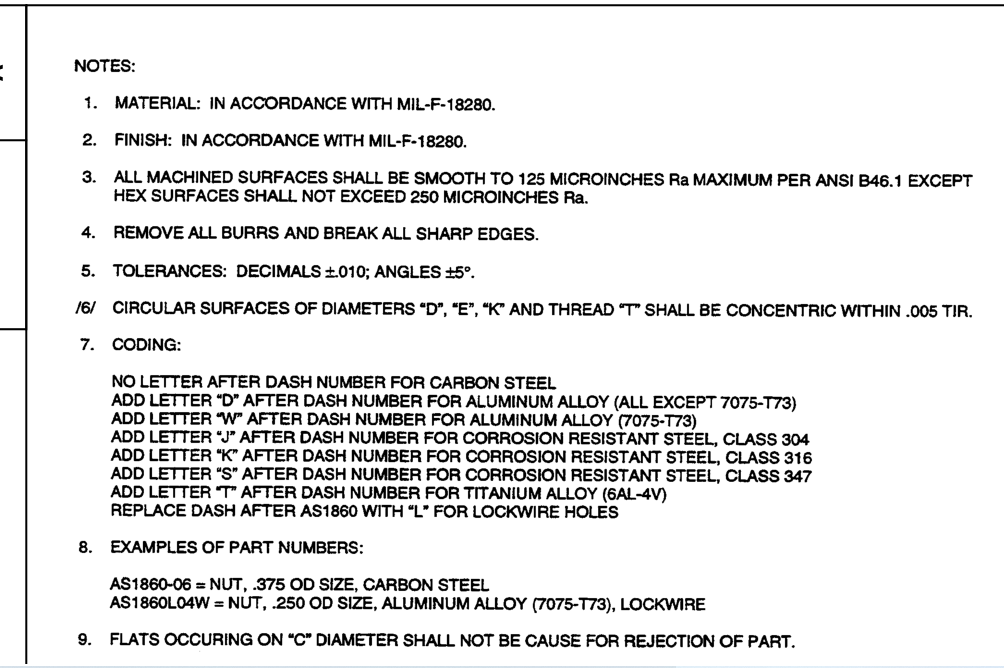

NOTES:

1. MATERIAL: IN ACCORDANCE WITH MIL-F-18280.

2. FINISH: IN ACCORDANCE WITH MIL-F-18280.

3. ALL MACHINED SURFACES SHALL BE SMOOTH TO 125 MICROINCHES Ra MAXIMUM PER ANSI B46.1 EXCEPT HEX SURFACES SHALL NOT EXCEED 250 MICROINCHES Ra.

4. REMOVE ALL BURRS AND BREAK ALL SHARP EDGES.

5. TOLERANCES: DECIMALS土010; ANGLES +5°.

6/ CIRCULAR SURFACES OF DIAMETERS “D”, “E”,“K* AND THREAD T SHALL BE CONCENTRIC WITHIN .005 TIR.

7. CODING:

NO LETTER AFTER DASH NUMBER FOR CARBON STEEL

ADD LETTER“D” AFTER DASH NUMBER FOR ALUMINUM ALLOY (ALL EXCEPT 7075-T73)

ADD LETTER W” AFTER DASH NUMBER FOR ALUMINUM ALLOY (7075-T73)

ADD LETTER“J” AFTER DASH NUMBER FOR CORROSION RESISTANT STEEL, CL ASS 304

ADD LETTER“4K” AFTER DASH NUMBER FOR CORROSION RESISTANT STEEL, CLASS 316

ADD LETTER “S” AFTER DASH NUMBER FOR CORROSION RESISTANT STEEL, CLASS 347

ADD LETTER T AFTER DASH NUMBER FOR TITANIUM ALLOY (6AL 4V) REPL ACE DASH AFTER AS1860 WITH L” FOR LOCKWIRE HOLES

8. EXAMPLES OF PART NUMBERS:

AS1860-06 = NUT, .375 OD SIZE, CARBON STEEL

AS1860L04W = NUT, .250 OD SIZE, ALUMINUM ALLOY (7075-T73), LOCKWIRE

9. FLATS OCCURING ON “C” DIAMETER SHALL NOT BE CAUSE FOR REJECTION OF PART.

10. INTENDED USE: FOR USE ON FLARELESS, NON-REVERSIBLE STYLE FITTING ASSEMBLY DESCRIBED ON AS1856.

11. THIS PART MEETS THE REQUIREMENTS OF MIL-F-18280.

SAE AS 1860A:2002 pdf download