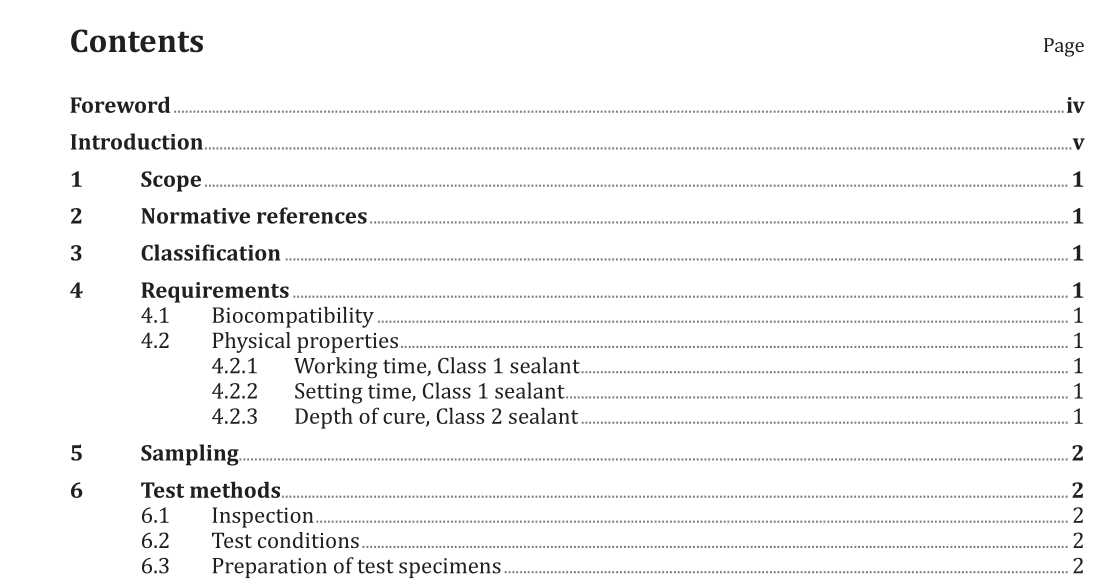

ISO 6874:2015 pdf download.Dentistry — Polymer-based pit and fissure sealants

1 Scope

This International Standard specifies requirements and test methods for polymer-based materials intended for sealing pits and fissures in teeth.

This International Standard covers both self-curing and external-energy-activated materials.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1942, Dentistry — Vocabulary

ISO 8601, Data elements and interchange formats — Information interchange — Representation of dates and times

3 Classification

For the purposes of this International Standard, polymer-based pit and fissure sealants are classified,according to the method of curing, as follows:

Class 1: Materials whose setting is effected by mixing an initiator and activator (“self-curing” materials).

Class 2: Materials whose setting is effected by the application of energy from an external source, such as visible light (“external-energy-activated” materials).

4 Requirements

4.1 Biocompatibility

See the Introduction for guidance on biocompatibility, ISO 7405 and ISO 10993-1.

4.2 Physical properties

4.2.1 Working time, Class 1 sealant

The working time for Class 1 sealants, determined in accordance with 6.4, shall not be less than 40 s.

4.2.2 Setting time, Class 1 sealant

The setting time for Class 1 sealants, determined in accordance with 6.5, shall not be greater than 5 min.

4.2.3 Depth of cure, Class 2 sealant

The depth of cure for Class 2 sealants, determined in accordance with 6.6, shall be not less than 1,5 mm.

If the material is supplied in more than one shade, each shade shall comply with this requirement.

6.4.1 Apparatus

6.4.1.1 Thermometry apparatus, as shown in Figure 1.

The apparatus consists of a piece of polyethylene (or similar material) tubing, A, located on a block of polyamide or similar material, B, which has a hole into which is inserted a stainless steel tube, C, containing a stabilized thermocouple D. The polyethylene tube A is 6 mm long, 4 mm in internal diameter and has a wall thickness of 1 mm. The locating part of block B is 4 mm in diameter and 2 mm high. When assembled, the two components form a specimen well 4 mm high × 4 mm in diameter. In order to facilitate removal of the specimen after testing, the thermocouple D has a conical tip that protrudes 1 mm into the base of the specimen well. The tolerances on the above-mentioned dimensions are ± 0,1 mm. The thermocouple consists of wires (0,25 ± 0,05) mm in diameter, made of a material (e.g. copper/constantan) capable of registering rapid temperature changes in a specimen of setting material to an accuracy of 0,1 °C. The thermocouple is connected to an instrument (e.g. voltmeter or chart recorder) capable of recording the temperature to that accuracy. NOTE A prefabricated thermocouple of similar size and performance can be substituted.

ISO 6874:2015 pdf download