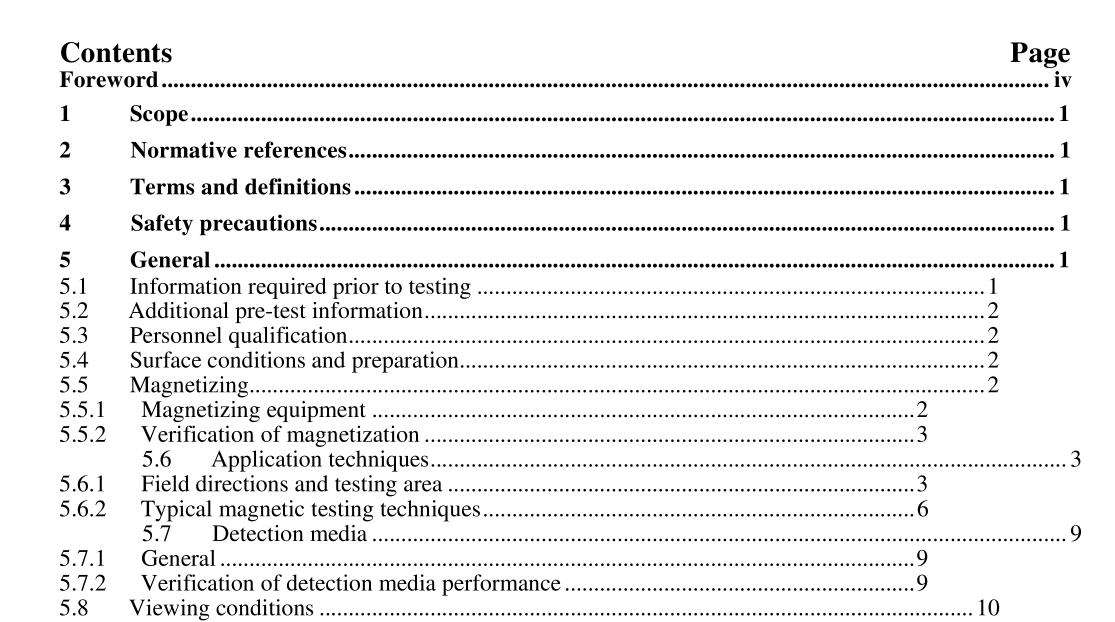

ISO 17638:2016 pdf download.Non-destructive testing of welds — Magnetic particle testing

1 Scope

This document specifies techniques for detection of surface imperfections in welds in ferromagnetic materials, including the heat affected zones, by means of magnetic particle testing. The techniques are suitable for most welding processes and joint configurations. Variations in the basic techniques that will provide a higher or lower test sensitivity are described in Annex A.

This document does not specify acceptance levels of the indications. Further information on acceptance levels for indications may be found in ISO 23278 or in product or application standards.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3059, Non-destructive testing — Penetrant testing and magnetic particle testing — Viewing conditions

ISO 9934-1:2015, Non-destructive testing — Magnetic particle testing — Part 1: General principles

ISO 9934-2, Non-destructive testing — Magnetic particle testing — Part 2: Detection media

ISO 9934-3, Non-destructive testing — Magnetic particle testing — Part 3: Equipment

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 12707 and ISO 17635 apply. ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/ohp

4 Safety precautions

Special consideration shall be given to toxic, inflammable and/or volatile materials, electrical safety and unfiltered UV radiation.

Magnetic particle testing often creates high magnetic fields close to the object under test and the magnetising equipment.

Items sensitive to these fields should be excluded from such areas.

5 General

5.1 Information required prior to testing

Prior to testing, the following items shall be specified (where applicable):

a) specific test procedure;

b) certification requirements for NDT personnel;

5.3 Personnel qualification

Magnetic particle testing of welds and the evaluation of results for final acceptance shall be performed by qualified and capable personnel. It is recommended that personnel be qualified in accordance with ISO 9712 or an equivalent standard at an appropriate level in the relevant industry sector.

5.4 Surface conditions and preparation

Areas to be tested shall be dry unless appropriate products for wet surfaces are used. It may be necessary to improve the surface condition, e.g. by use of abrasive paper or local grinding to permit accurate interpretation of indications.

Any cleaning or surface preparation shall not be detrimental to the material, the surface finish or the magnetic testing media. Detection media shall be used within the temperature range limitations set by the manufacturer.

5.5 Magnetizing

5.5.1 Magnetizing equipment

General magnetization requirements shall be in accordance with ISO 9934-1:2015, Clause 8.Unless otherwise specified, for example, in an application standard, the following types of alternating current-magnetizing equipment shall be used:

ISO 17638:2016 pdf download