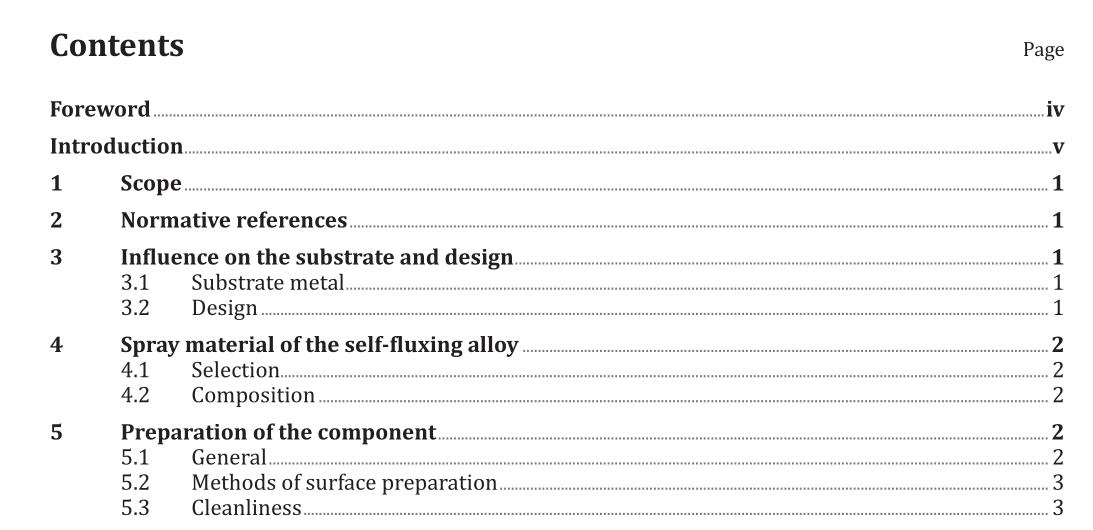

ISO 14920:2015 pdf download.Thermal spraying — Spraying and fusing of self-fluxing alloys

1 Scope

This International standard defines the procedure for thermal spraying of self-fluxing alloys that are simultaneously or subsequently fused to create a homogeneous, diffusion bonded coating.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 11124-1, Preparation of steel substrates before application of paints and related products —Specifications for metallic blast-cleaning abrasives — Part 1: General introduction and classification

ISO 11126-1, Preparation of steel substrates before application of paints and related products —Specifications for non-metallic blast-cleaning abrasives — Part 1: General introduction and classification

ISO 12679, Thermal spraying — Recommendations for thermal spraying

ISO 14924, Thermal spraying — Post-treatment and finishing of thermally sprayed coatings

EN 1274, Thermal spraying — Powders — Composition, technical supply conditions

EN 13507, Thermal spraying — Pre-treatment of surfaces of metallic parts and components for thermal spraying

3 Influence on the substrate and design

3.1 Substrate metal

Due to the heat transfer into the substrate metal when fusing the coating, in order to bond the coating with the substrate metal by diffusion, the possible effects of such heating on the substrate metal shall be considered:

a) scaling;

b) the need to stress relieve;

c) an irreversible transformation of the mechanical and/or metallurgical properties.

Martensitic steels are susceptible to stress cracking and alloys containing significant amounts of C, Al,Ti, Mg, S, sulfides, P, and nitrogen can create porosity in the coating and may render the substrate metal liable to stress cracking.

3.2 Design

The preparation of the component for spraying and fusing of a coating usually includes a reduction of the design dimensions, if pre-machining is applied. Consideration shall be given to the effect of such a reduction on the loading of the component, as the coating does not contribute to the strength of the component. Consideration shall be given, to the fact that the sprayed and fused coating will have differing physical properties to the substrate material.

The fatigue strength, the deformation resistance, and other properties of the component can be affected by the application of the coating.

Due to the heat input during fusing unacceptable deformation of the component may occur. Measures to prevent distortion or deformation can be used, such as, to erect or hang the parts along their centre-of- gravity axis or by the use of supporting jigs.

ISO 14920:2015 pdf download