IEEE Std 1568:2003 pdf free download.IEEE Recommended Practice for Electrical Sizing of Nickel-Cadmium Batteries for Rail Passenger Vehicles.

If cells of sufficiently large capacity arc not available, the battery manufacturer should be consulted for any limitation on paralleling.

Operating conditions can change the available capacity of the battery. For example:

a) The available capacity decreases as its temperature decreases:

b) The available capacity decreases as the discharge rate increases:

c) The minimum specified battery voltage at any time during the discharge cycle limits the available capacity:

d) The charging method affects the available capacity;

e) The frequency, depth of discharge and lime available for recharge affects the available capacity:

1) The battery temperature during charge affects the available capacity.

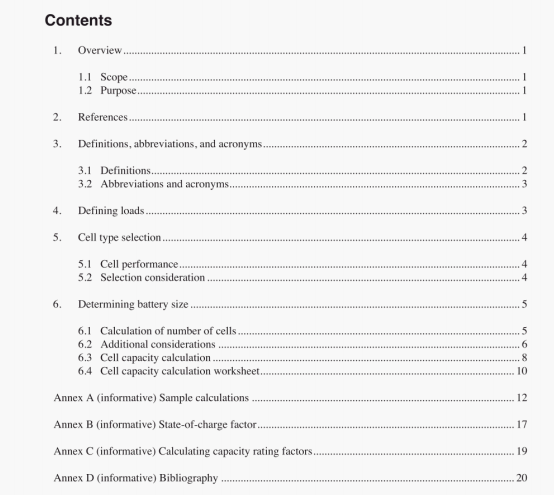

6.1 Calculation of number of cells

The battery charging voltage, as well as maximum and minimum allowable system voltages, determine the number of cells in the battery. It has been common practice to use 18—20,24-26. 36—40.48—52 or 75—90 cells for the nominal system voltages of 24. 32. 48. 64 or 110 V. respectively (IEEE Std l476-2XX outlines the voltage ranges for 24. 32.48 and 64 V nominal voltages).

NOTE —ihe use of a larger number of cclk allos lower nilnimum cell voltage and. therefore. smalkr cdl capacity for the duty cycle.

Initially the number of cells should he determined by dividing the nominal LVPS output voltage (see Table 4 of IEEE Std 1476.20(X) I by the battery manufacturer’s recommended cell voltage required for satisfactory charging at 20°C. When temperature compensation is used to control the LVPS output voltage, and battery voltage is not allowed to exceed a given maximum system voltage, the number of cells will be limited by the battery manufacturer’s recommended cell voltage required for satisfactory charging at low temperature. In this case, the initially calculated number of cells may be reexamined or compromise temperature compensa. hon requirements may be adopted.

NOTE—For dedicated oft-line battery chargen. the recommended baner supplier’s chardng voltage can be used without limiting number of cells or temperature compensation.

The time required to recharge a discharged battery decreases as the charging voltage per cell increases, assuming that the charging equipment can supply the high current necessary early in the recharge cycle. Therefore, it is necessary to select the number of cells that can be adequately recharged in the time available.

IEEE Std 1568:2003 pdf free download