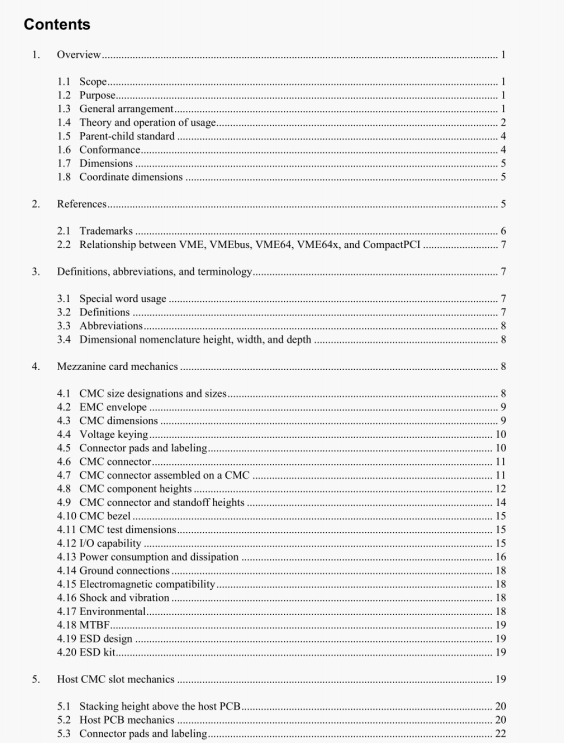

IEEE Std 1386:2001 pdf free download.IEEE Standard for a Common Mezzanine Card (CMC) Family and IEEE Standard Physical and Environmental Layers for PCI Mezzanine Cards (PMC).

4.10 CMC bezel

The bezel of a CMC has two basic parts: the bezel and the EMU gasket.

Each PMC shall be designed to accommodate a bezel. The main function of the bezel is for the mounting of front panel 1.0 connectors and/or special indicators and switches. Since standard-size bezels are used, the CMC can lit into any host which provides a UMU slot. Figure 12 shows the mechanical design of the CMC bezel.

The two legs on the bezel also provide the standoffs for the front portion of the mezzanine card. The height of these legs shall be the same as the two standot used itear the CM(’ connectors.

Should the PMC PCH be moved up or down within the PMC envelope, then the bezel leg height shall be adjusted accordingly. See Table 2 for this relationship.

The center horizontal line of the PMC bezel shall always be 5.5 mm above the host side I surface, for the 10 mm stacking height. See Figure 10 for this illustration. Note that if the CMC PCB is moved up or down, the CMC bezel’s center line does not move. The bezel always maintains the same relationship with the host’s side I surface and host front panel (face plate).

4.11 CMC test dimensions

It is very important that fully assembled CMCs be measured to ensure that when the CMC is plugged into a host’s PMC slot, it will properly match. There are three critical dimensions that shall be measured to verify that a (‘MC will fit properly in a host computer’s PMC slot.

The first critical dimension is the distance between rear connectors (0.(N) reference and the PMC bezel center line. When a PMC is plugged into the host computer’s PMC slot. the PMC bezel should he aligned with the host computer’s CMC slot opening. Due to tolerance buildup, this will not perfectly match. The actual mismatch may be as much as ±0.3 mm. See Figure 13.

The second critical dimension is the perpendicular center line of the PMC connector to the perpendicular center line of the CMC bezel. This is specified in Figure 13.

The third critical dimension is the vertical height of the CMC bezel and standotTs off the CMC reference plane. The center of the bczcl shall be within the tolerance specified in Figure 10 and the standoffs with the numbers given in Table 2.

4.12 110 capability

The 1.0 capability may be via the CMC front panel, backplane 10 via host, or both.

For 1/0 through the host’s backplane, such as VME64x, CompactPCl. Multibus I, or Multibus II. one or more of the CMC connectors may be assigned for this capability. See Clause 6 of this standard for the required mappings.

IEEE Std 1386:2001 pdf free download