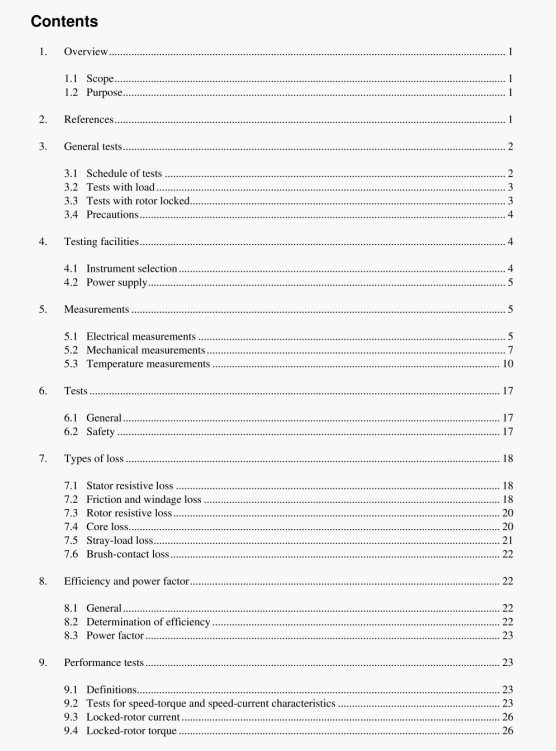

IEEE Std 114:2001 pdf free download.IEEE Standard Test Procedure for Single-Phase Induction Motors.

5.3 Temperature measurements

Temperature measurements are made to determine

a) Ambient temperature.

b) Temperature rise of certain parts of the motor above the ambient temperature when the motor is running at specified load.

C) Rapidly changing temperatures of certain pails of the motor, such as windings.

5.3.1 Methods of measuring temperature

Commonly used methods of temperature determination are defined in IEEE SW 1-1986. Table 2, and as follows:

a) Thermometer

b) Applied thermocouple

C) Contact thermocouple

d) Resistance

e) Embedded detector

Methods of measuring motor-winding temperature are described in IEEE Std 1-1986. IEEE Std 118-1978, and IEEE Std 119-1974. These methods can be classified into two categories according to their principle of operation. One category consists of methods employing a temperature-sensing element located in thermal contact with the windings. An applied thermocouple is an example of a sensing element used in this way. The other category includes those methods that sense the change of a physical property of the winding conductor material with temperature. The resistance method is based on a change of electrical resistivity with temperature and is an example of this category of methods.

5.3.2 Thermometer method

Liquid-in-glass thermometers should be examined for broken liquid columns before use. The thermometer bulb should be secured in position with a kIt pad. a small piece of putty. or the equivalent, in such a manner as to shield it from the surrounding air. The thermometer bulb should not be higher than the stem. There should be no restriction of the natural windage of the motor or of the heat radiation from the coil being measured. The thermometer is applied to the hottest parts accessible without alteration of the structure.

The temperature shall be measured on the surface of the coil ends at two peripherally spaced locations.

Bimetallic, liquid-in-glass, and resistance thermometers are not recommended for use in measuring transient temperatures of motor windings. The sue and shape of these thermometers make them difficult to apply to windings. Additionally. the large (hernial capacity of these thermometers and the low thermal conductance from the windings may resuh in significant errors when measuring ransient temperatures.

IEEE Std 114:2001 pdf free download