IEEE 738:2012 pdf free download.IEEE Standard for Calculating the Current-Temperature Relationship of Bare Overhead Conductors.

After a period of time. At, the conductor tempcraturc has increased by a tempcraturc change of The incrcas.ed conductor tcmperaturc yields higher heat losses due to convection and radiation and somcwhat higher Joule heat generation due to the increased conductor resistance. From & to 2Ai. the conductor temperature continues to increase, but does so at a lower rate. After a large number of such time ititersals. the conductor temperature approaches its final steady-state temperature (T1).

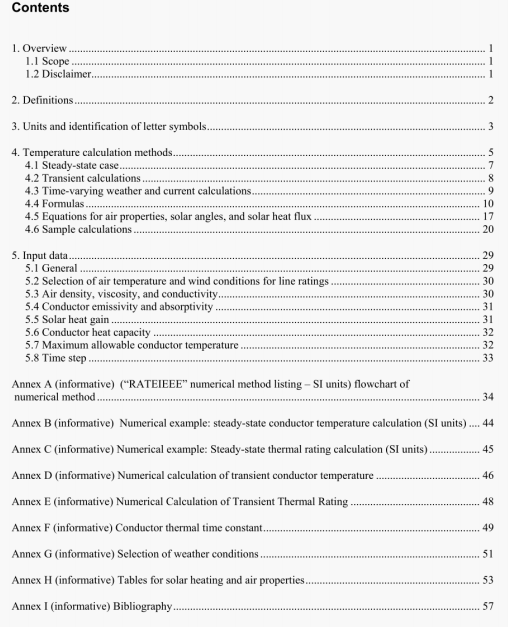

During each intersal of time. A,. the corresponding increase in conductor temperature may be eakulaled using the formulas given in 4.4. The computer program included in Annex A calculates the conductor tcmpcrature as a function of time after the step change in current.

As described in Annex F. the rate of change in bare overhead conductor temperature is approximately exponential. ssiih a thermal time constant that is on the order of 5 mm to 20 mm for typical transmission conductors where the longest time constant corresponds to the largest conductors. With reference to Figure I. this implies that the conductor temperature increases to its final value in a time period of 15 mm to 60 mm. Transient ratings arc therefore typically calculated for emergency currents persisting for 5 nun and 30 mm.

Accuracy in the iterative transient calculation requires that the time interval chosen be sufficiently small with respect to the thermal time Constant. It is always prudent to rerun the calculation with a smaller timc interval to check whether the calculated values change. For most calculations with typical bare overhead stranded conductors, a calculation interval of 10 seconds or lcs is sufficient.

4.2.2 Transient thermal rating

The transient thermal rating is normally calculated by repeating the preceding calculations of T..5(t) over a range oi1 values, then selcvtmg the I value that causes the conductor temperature to reach its maxirnuni allowable value in the allotted time.

4.2.3 Fault current calculations

Conductor temperature changes in response to “fault” currents arc calculated in the same manner a.s in 4.2.1. except that the step increase in current is usually quite large ( 10 000 A). the corresponding time to reach maximum allowable temperature is typically short f.: I s). and the maximum temperatures attained may approach the melting pomi of aluminum or copper. These calculations are essentially adiabatic because the hcat loss by convection and radiation during such short times is negligible in companson to the hcat stored in the conductor.

With non-homogeneous conductors, such as aluminum conductor steel reinforced (ACSR). the heat generation in the lower conductivity steel core is much lower than in the surrounding aluminum strand layers. The resulting temperature difference between the core and the surrounding aluminuni strands abates after no more than 60 seconds from any step change in current. This is discussed further in 4,4.K,

4.3 Time-varying weather and current calculations

The tcmpcrature of an overhead power conductor is constantly changing in response to changes in electrical current and weather. The thermal model described in this standard may be applied to this case. To do this the user must perfonn a series of calculations, each applying to a short period of time (as was done for the transient case) during which the current and weather parameters (wind sped and direction, ambient temperature. etc.) are assumed to remain con.tant and equal to their values at the beginning of the interval.

IEEE 738:2012 pdf free download