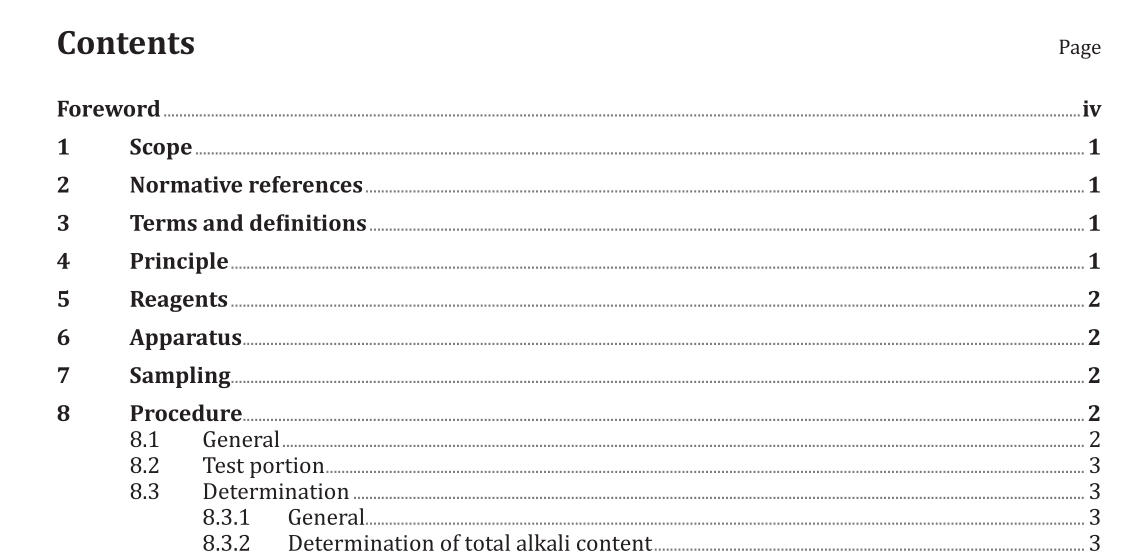

BS ISO 685:2020 pdf download.Analysis of soaps — Determination of total alkali content and total fatty matter content

1 Scope

This document specifies a method for the simultaneous determination of the total alkali content and the total fatty matter content of soaps (including liquid soaps), excluding compounded products.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3819, Laboratory glassware — Beakers

ISO 8212, Soaps and detergents — Techniques of sampling during manufacture

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1 total alkali

sum of the alkali bases combined as soap with fatty and rosin acids, as well as those corresponding to free alkali metal hydroxides or carbonates and to any silicates present which will be titrated under the test conditions

Note 1 to entry: The results are expressed as a percentage mass fraction of either sodium hydroxide (NaOH) or of potassium hydroxide (KOH), according to whether sodium or potassium soaps are concerned.

3.2 total fatty matter

water‑insoluble fatty material obtained by decomposing the soap with a mineral acid under the conditions specified

Note 1 to entry: This term includes unsaponifiable matter, glycerides and any rosin acids contained in the soap,in addition to the fatty acids.

4 Principle

Decomposition of the soap by a known volume of standard volumetric mineral acid solution, extraction and separation of the liberated fatty matter with light petroleum and determination of the total alkali content by titration of the excess of acid contained in the aqueous phase with a standard volumetric sodium hydroxide solution. After evaporation of the light petroleum from the extract, dissolution of the residue in ethanol and neutralization of the fatty acids with a standard volumetric potassium hydroxide solution. Evaporation of the ethanol and weighing of the soap formed to determine the total fatty matter content.

8.3.1 General

Dissolve the test portion (8.2) in about 100 ml of hot water. Pour the solution into one of the separating funnels (6.2) or into the extraction cylinder (6.3) and wash the beaker with small quantities of water, adding the washings to the separating funnel or to the extraction cylinder. Add a few drops of the methyl orange solution (5.7) and then, from a burette, add, while vigorously shaking the separating funnel or the extraction cylinder, an accurately measured known volume of the sulphuric acid solution (5.4) until there is an excess of about 10 ml. Cool the contents of the separating funnel or of the extraction cylinder to about 25 °C and add 100 ml of the light petroleum (5.2). Insert the stopper and gently invert the separating funnel or the extraction cylinder, while maintaining a hold on the stopper. Open the stopcock of the separating funnel or the stopper of the extraction cylinder gradually to release any pressure, then close, gently shake and again release the pressure. Repeat the shaking until the water phase is clearly separated from the organic phase

BS ISO 685:2020 pdf download