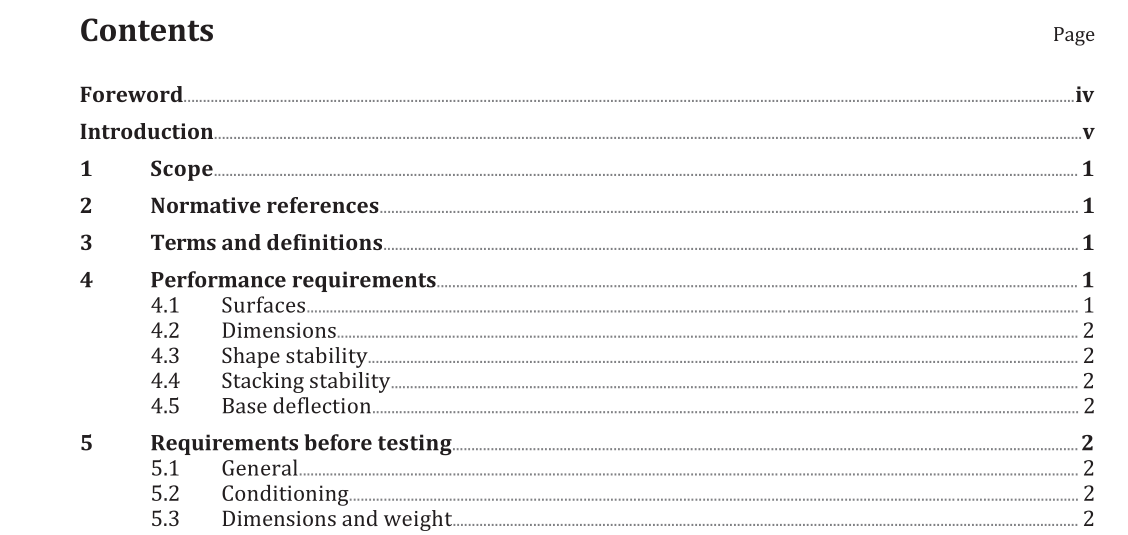

BS ISO 18616-2:2016 pdf download.Transport packaging — Reusable, rigid plastic distribution boxes

1 Scope

This document specifies the test methods for handling and managing reusable, rigid plastic distribution boxes. These boxes are based on the modular area 600 mm × 400 mm, 600 mm × 500 mm,550 mm × 366 mm and subdivisions of them.

This document is designed for general purpose applications in a returnable transport system. For automotive industry application, ISO 19709-1, ISO/TS 19709-2 and ISO/TS 19709-3 can be referenced.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 2206, Packaging — Complete, filled transport packages — Identification of parts when testing

ISO 2233, Packaging — Complete, filled transport packages — Conditioning for testing

ISO 2234, Packaging — Complete, filled transport packages and unit loads — Stacking tests using static load

ISO 2248, Packaging — Complete, filled transport packages — Vertical impact test by dropping

ISO 3394, Packaging — Complete, filled transport packages and unit loads — Dimensions of rigid rectangular packages

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 18616-1 and ISO 21067 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

4 Performance requirements

4.1 Surfaces

The box shall be free from foreign bodies, blowholes, cracks and burrs and granules which have not melted, as well as from other defects. Minor unevenness or sunken areas produced in processing are permissible provided that fitness for use is not adversely affected.

4.2 Dimensions

Tolerances on nominal sizes shall be not greater than ±0,5 %.

The plan view sizes shall not exceed the modular sizes as given in ISO 3394.

Tolerances on nominal tare mass shall not exceed ±3 %.

4.3 Shape stability

When tested in accordance with 6.2, boxes shall exhibit no visible change or damage such as cracks or embedding. No deformation which reduces the functions of the box shall be acceptable.

4.4 Stacking stability

When tested in accordance with 6.1, stacks of three boxes shall keep their equilibrium during and after the test.

The reduction of the height of the stack under load shall be less than 2 % of the first measurement (taken between the first and second measurement).

The residual reduction of the height of the stack shall be less than 1 % of the first measurement (taken between the first and third measurement).

4.5 Base deflection

When tested in accordance with 6.3, the deflection under load shall be less than 3 % of the actual base diagonal length (taken between the first and second measurement).

The residual deflection shall be less than 1 % of the actual base diagonal length (taken between the first and third measurement).

BS ISO 18616-2:2016 pdf download