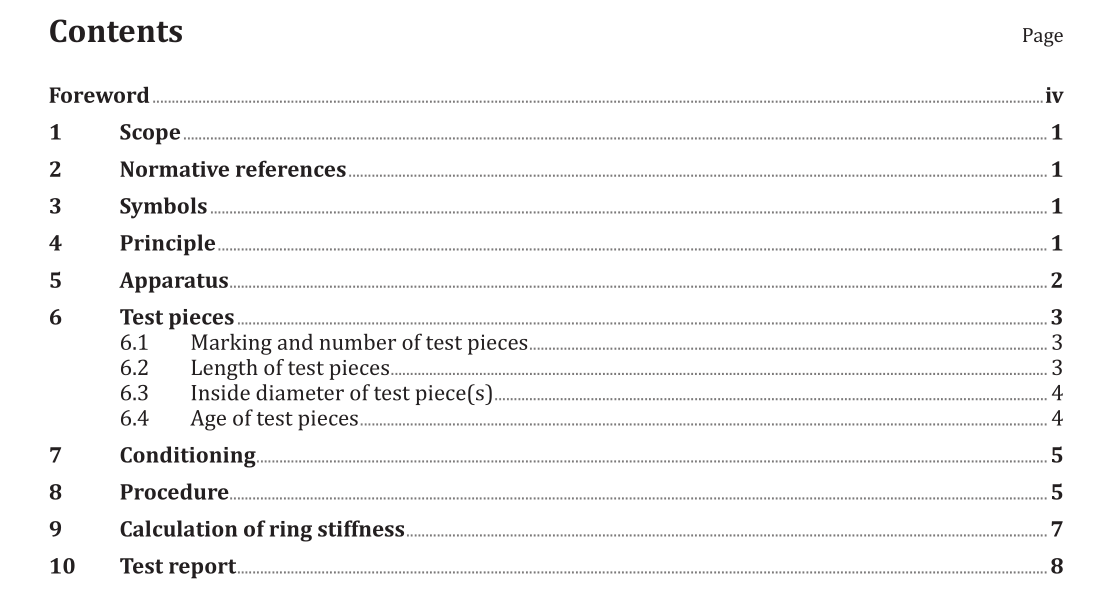

ISO 9969:2016 pdf download.Thermoplastics pipes — Determination of ring stiffness

1 Scope

This International Standard specifies a test method for determining the ring stiffness of thermoplastics pipes having a circular cross section.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3126, Plastics piping systems — Plastics components — Determination of dimensions

4 Principle

The ring stiffness is determined by measuring the force and the deflection while deflecting the pipe at a constant deflection speed. A cut length of pipe supported horizontally is compressed vertically between two parallel flat plates moved at a constant speed that is dependent upon the diameter of the pipe. A plot of force versus deflection is generated. The ring stiffness is calculated as a function of the force necessary to produce a 3 % diametric deflection of the pipe. NOTE It is assumed that the test temperature is set by the referring standard, if appropriate (see 8.1).

5 Apparatus

5.1 Compressive testing machine, capable of a constant rate of crosshead movement, via a pair of parallel plates (5.2), as appropriate to the nominal diameter of the pipe in conformance with Table 1,with sufficient force and travel to produce the specified diametric deflection (see Clause 8).

5.2 A pair of hard and rigid plates, through which the testing machine can apply the necessary force,F, to the test piece.

The plates shall have flat, smooth and clean surfaces for contact with the test piece.

The stiffness and hardness of each plate shall be sufficient to prevent bending or deformation to an extent that would affect the results.

The length of each plate shall be at least equal to the length of the test piece. The width of each plate shall not be less than the width of the contact surface with the test piece while under load plus 25 mm.

5.3 Dimensional measuring devices, capable of determining

— individual values for the length of a test piece (see 6.2.2 and 6.2.3) to with an accuracy of ± 1 mm,

— the inside diameter of a test piece to with an accuracy of ± 0,5 %, and

— the change of inside diameter of a test piece in the direction of loading with an accuracy of 0,1 mm or 1 % of the deflection, whichever is the greater.

An example of a device for measuring the inside diameter of corrugated pipe is shown in Figure 1.

ISO 9969:2016 pdf download